The Impact of Design for X

Design for X solutions provide product and organization transformations that impact the bottom line.

The goal of DFX is to focus attention on the variable and/or feature of interest capable of creating the desired outcome, given all other related considerations. The target outcome of using the Design for X (DFX) approach is to create sustainable business advantage in a rapidly changing global market.

What is Design for X?

Design for X (DFX) is an approach to engineering and design that focuses on a primary variable of a product or process, and narrows in on the design activities that will influence that trait or feature as the desired outcome of a project. DFX is often employed to improve a product in the face of new competition or a market shift, extend the lifecycle (and profits) of an existing product who's components are harder to come by, or to quickly solve a new performance or compliance issue that has arisen. However, the focus and discipline of DFX can be a much more powerful tool if used as part of a broader strategical approach to developing product/process differentiation, and a sustainable advantage against competition.

Real, Sustainable Impact from using Design for X

As we discussed in a previous DFX article, strategic development of products and services can be extended to have a larger impact when DFX principles are applied. We discussed a focus on strategy to align your designs will future growth, designing for competitive advantage to differentiate you from competition, and starting your design process with DFX to ensure you take advantage of the approach's true value. Here are several actual cases where DFX principles were applied, and the actual outcome of the projects in terms of creating the business value you are seeking.

- Design For Manufacturing leads to improved manufacturing processes to save time and money, plus a new product that opened markets by broadening a snowboard company's compatibility in the marketplace.

- Design for Testability provides true competitive advantage to designers and trainers of Unmanned Arial Systems by providing a consistent environment and advanced data collection for further analysis.

- Design for Performance improved a rechargeable tool to allow for better acceptance in the market while simultaneously reducing manufacturing costs and reducing part inventory count.

- Design for Compliance took the rigid standards applied to FDA testing equipment and designed a product to disrupt rapid testing at the Outbreak of the COVID 19 pandemic.

- Design for Manufacturing embraces the urgency of the moment and the need to build an open-source mechanical ventilator using readily available components.

In Summary

DFX is a tool that helps to understand the power of design in outcomes. But too narrow of a focus could result in multiple design iterations and unforeseen design conflicts within a company's products. It's important to focus on the objectives of your DFX, while also keeping broader design principles in mind.

Once again: Start Your Design with DFX

Once your team has determined the focus of your strategy, place the focus of design on that characteristic. The product development should be centered on driving that initiative. While other design aspects should and will be considered, your team should be asking how it affects the primary objective. In the case mentioned above, that objective is cost.

These questions shouldn't just pertain to the current iteration or time frame. It's not enough to ask "Does this reduce or increase costs?" You must also consider factors such as "What is the risk that this will increase costs in the future?", "What technologies are coming on line that will drive down the costs in the future?" Every decision that whittles away a cost saving now, or eliminates a cost saving opportunity in the future, will put your competitive advantage at risk.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

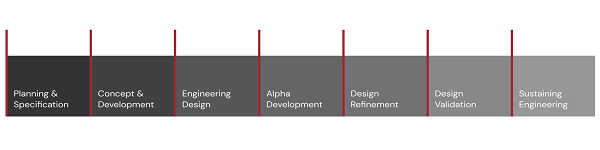

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

A focus on your product. Manufacturability is embedded throughout our product development process to achieve cost, feature, and performance requirements. Our product development plans target your manufacturing, cost, timeline, reliability and supply chain needs, as well as other critical requirements.

A focus on your product. Manufacturability is embedded throughout our product development process to achieve cost, feature, and performance requirements. Our product development plans target your manufacturing, cost, timeline, reliability and supply chain needs, as well as other critical requirements.

Our primary DFX capabilities include:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (and Product Platform Design)

Don't see your requirement here? Try Us! We can engineer what many others can only imagine.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!