Sustainability & Resilience: Building Operations That Last

In an era marked by climate change, resource constraints, and unprecedented disruptions, businesses face a dual imperative: minimize environmental impact while maintaining operational continuity through challenges.

Smart Operations create systems that not only reduce environmental footprint but also withstand and recover from unexpected shocks.

The Dual Power of Sustainable, Resilient Operations

At first glance, sustainability and resilience might seem like separate goals. However, in the context of smart operations, they form a powerful synergy. Sustainability focuses on responsible resource usage and minimizing environmental impact, while resilience enables operations to absorb shocks, adapt to changing conditions, and recover quickly from disruptions. Together, these capabilities create operations that are both environmentally responsible and remarkably durable.

Let's explore how this vital outcome drives business performance in today's challenging landscape.

Continue reading below to learn more

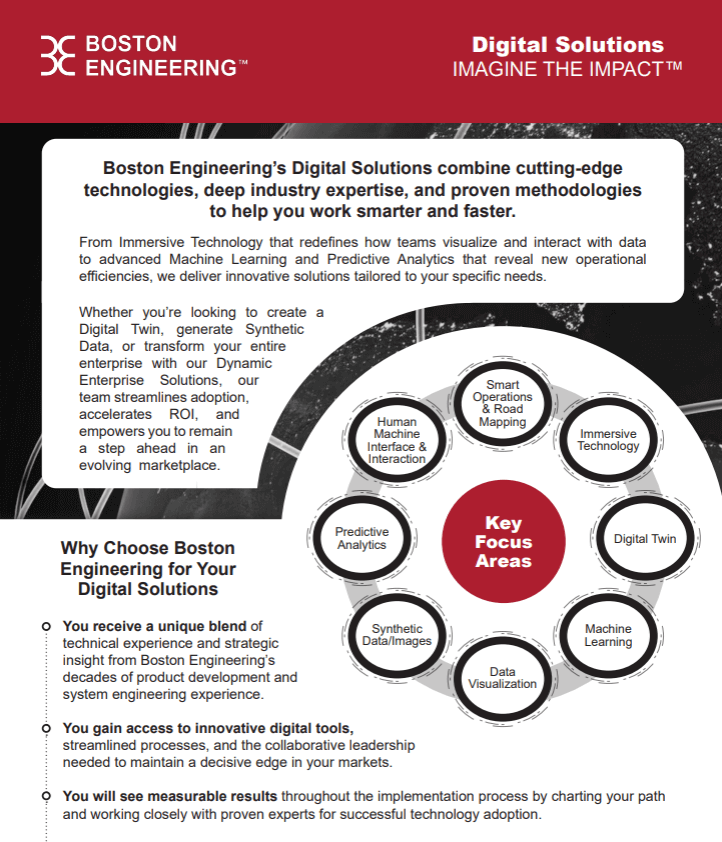

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

How Sustainability & Resilience Drive Business Performance

Resource Optimization and Cost Reduction

Smart operations enable unprecedented visibility into resource consumption, revealing opportunities for efficiency that were previously hidden.

Imagine a metal fabrication company implements sensors throughout its production facilities to monitor energy, water, and material usage in real-time. The system identifies unexpected patterns of resource waste during shift transitions and machine setups. By addressing these issues, the company can significantly reduce energy consumption, water usage, and material waste. These sustainability improvements directly translate in annual cost savings while reducing the company's carbon footprint.

Enhanced Business Continuity

Resilient operations maintain functionality during disruptions that would cripple traditional systems, preserving revenue and customer relationships.

For example, a specialty food processor can build redundancy and flexibility into its production network through smart operations technologies. If severe flooding disables one of its major facilities, the company's intelligent control systems automatically redistribute production orders to alternative sites based on available capacity and capabilities. The digital systems ensure that product specifications are consistently maintained despite the shift in production location. While competitors experience weeks of downtime following the same weather event, this company can resume most of its normal output, maintaining critical customer relationships and capturing new business from less resilient competitors.

For example, a specialty food processor can build redundancy and flexibility into its production network through smart operations technologies. If severe flooding disables one of its major facilities, the company's intelligent control systems automatically redistribute production orders to alternative sites based on available capacity and capabilities. The digital systems ensure that product specifications are consistently maintained despite the shift in production location. While competitors experience weeks of downtime following the same weather event, this company can resume most of its normal output, maintaining critical customer relationships and capturing new business from less resilient competitors.

Regulatory Compliance and Market Access

As environmental regulations tighten globally, sustainable operations ensure continued market access and avoid costly penalties.

Imagine a chemical manufacturer implements advanced monitoring and control systems to track emissions and resource usage across its operations. The system can provide automated regulatory reporting with verification of compliance across multiple jurisdictions. When a key export market suddenly implements stricter environmental standards, the company can immediately demonstrate compliance while competitors scramble to adapt their reporting processes. This capability preserves access to the market segment and positions the company as a preferred supplier for environmentally conscious customers.

Supply Chain Resilience

Smart operations extend sustainability and resilience beyond company walls to encompass the entire value chain.

Imagine a consumer goods company develops a digital supply chain monitoring system that tracks environmental metrics and risk factors across its supplier network. If drought conditions threaten agricultural inputs from a key region, the system can identify the emerging risk months before actual shortages occur. The company can proactively diversify sourcing to more climate-resilient regions while helping existing suppliers implement water conservation technologies. This approach maintains production continuity while competitors may face ingredient shortages and price spikes. Additionally, the reduced water footprint across the supply chain can be a valuable marketing asset with increasingly eco-conscious consumers.

Improved Stakeholder Relations

Sustainable, resilient operations strengthen relationships with investors, customers, and communities.

Consider the following example: A manufacturing company leverages smart operations to achieve and verify ambitious sustainability targets and documents a reduction in carbon intensity. This verified performance can unlock access to sustainability-linked financing that will reduce borrowing costs. Simultaneously, the company's resilience during industry disruptions can reduce insurance premiums as underwriters recognized the lower risk profile.

Contact us to talk about similar opportunities in your operations

Building Blocks of Sustainable, Resilient Operations

Several key technologies and approaches enable this powerful outcome:

- Connected monitoring systems provide visibility into resource usage and operational conditions, enabling both efficiency improvements and early warning of potential disruptions.

- Intelligent control platforms automatically optimize processes for efficiency while adapting to changing conditions.

- Predictive analytics identify sustainability opportunities and potential resilience threats before they become critical.

- Flexible production systems enable rapid reconfiguration in response to disruptions or resource constraints.

- Digital twins allow testing of sustainability improvements and resilience scenarios without risking operational disruption.

Contact us to talk about similar opportunities in your operations

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Implementation Principles for Success

Organizations seeking to enhance sustainability and resilience through smart operations should consider these implementation principles:

- Integrate sustainability and resilience objectives from the start rather than treating them as separate initiatives.

- Prioritize data collection and visibility as the foundation for both environmental improvement and risk management.

- Focus on material impacts by identifying the most significant environmental footprints and the most likely disruption scenarios.

- Build capabilities progressively, starting with foundational monitoring and gradually adding intelligent control and predictive capabilities.

- Measure and communicate outcomes to strengthen stakeholder relationships and build momentum for continued improvement.

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Conclusion

In a business environment characterized by environmental pressures and operational disruptions, sustainability and resilience have become essential business imperatives rather than optional initiatives. Smart operations provide the technological foundation and organizational approach needed to achieve both outcomes simultaneously.

Companies that successfully implement smart operations gain the ability to minimize environmental impact while maintaining business continuity through disruptions. This powerful combination doesn't just improve current performance—it creates the foundation for long-term viability in a world of increasing environmental constraints and operational challenges.

As business leaders look to secure their companies' futures, investments in sustainable, resilient operations aren't merely good corporate citizenship—they're essential risk management and competitive differentiation in an increasingly volatile world.

Partner with Boston Engineering to develop your roadmap for connectivity and data-driven decision-making. Our multidisciplinary expertise ensures seamless integration across technologies and systems, delivering transformative results for your operations.

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!