Predictive & Proactive Maintenance: Driving Performance Through Smart Operations

By anticipating equipment issues before they occur and taking action to prevent them, businesses can boost efficiency, lower costs, and gain a competitive edge.

Unplanned downtime and reactive repair strategies can severely impact performance, customer satisfaction, and the bottom line. Smart Operations offer a transformative solution, with Predictive & Proactive Maintenance emerging as one of the most valuable outcomes

The Strategic Value of Predictive & Proactive Maintenance

Predictive & Proactive Maintenance changes the game. It uses real-time operational data, intelligent algorithms, and automated systems to predict failures before they occur and proactively schedule interventions. The result is reduced downtime, optimized maintenance schedules, and extended equipment life.

Performance Improvements in Action

Companies that implement Predictive & Proactive Maintenance through smart operations realize tangible improvements:

- Reduced Downtime: Equipment issues are resolved before causing failures, minimizing costly production stoppages.

- Lower Maintenance Costs: Resources are used efficiently—servicing only when needed, rather than on a fixed schedule.

- Increased Asset Longevity: Real-time insights allow for better care of high-value assets.

- Higher Operational Efficiency: Maintenance teams are empowered to focus on value-added activities.

- Improved Safety: Risk of hazardous breakdowns is minimized through early detection and intervention.

Consider these potential examples:

- A global food processing company reduced unscheduled downtime by implementing condition-based monitoring on critical conveyor systems.

- A water utility used predictive analytics to reduce maintenance costs by identifying pump degradation before service disruptions occurred.

- An electronics manufacturer extended equipment life cycles through smart sensors and remote diagnostics, avoiding unnecessary replacements.

Where would a company begin to investigate these types of potential impact?

Continue reading below to learn more

The Boston Engineering Digital Solutions Portfolio

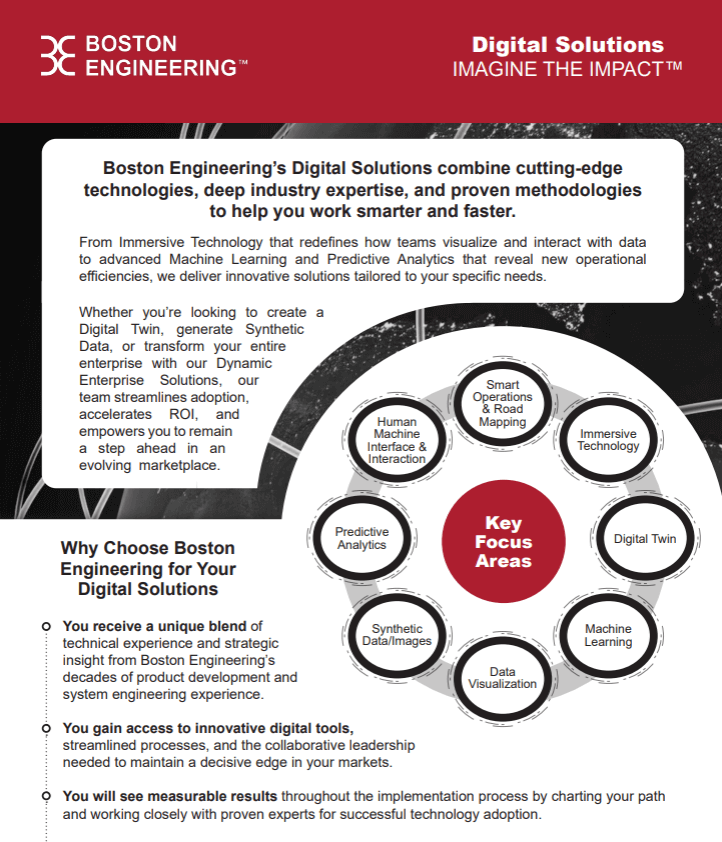

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Technology as the Enabler

The success of Predictive & Proactive Maintenance in smart operations relies on a suite of integrated technologies:

- IIoT (Industrial Internet of Things) delivers real-time machine data to inform maintenance decisions.

- AI & ML predict failures by recognizing subtle patterns in performance data.

- Robotics & Automation perform inspections and even execute repairs without interrupting operations.

- Digital Twin Technology simulates performance scenarios to forecast and prevent equipment issues.

- Advanced Control & Embedded Systems fine-tune operations to minimize wear and tear.

- Cybersecurity & Cloud Computing ensure that data is secure, accessible, and actionable in real time.

These technologies, working together, deliver the insight and automation needed for Predictive & Proactive Maintenance to become a strategic advantage.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Conclusion

Smart operations aren’t just about efficiency—they're about foresight. Predictive & Proactive Maintenance empowers companies to act before problems arise, boosting reliability, safety, and profitability.

Connect with us to learn how we can help you reduce unplanned downtime, extend equipment life, and enhance your operational performance through smart, proactive maintenance strategies.

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!