Continuous Process Optimization: Driving Excellence Through Smart Operations

In an increasingly competitive global landscape, businesses must do more than just keep up—they must continuously improve.

The ability to identify inefficiencies, adjust dynamically, and extract more value from operations is a defining characteristic of high-performing organizations. Continuous Process Optimization, a key outcome of Smart Operations, enables companies to fine-tune their operations in real time, uncover hidden performance gains, and sustain a competitive advantage.

Smart Operations integrate technologies that monitor, analyze, and adjust systems on the fly. Instead of periodic audits or scheduled improvements, optimization becomes a continuous, automated process that evolves with the operation.

Continue reading below to learn more

The Boston Engineering Digital Solutions Portfolio

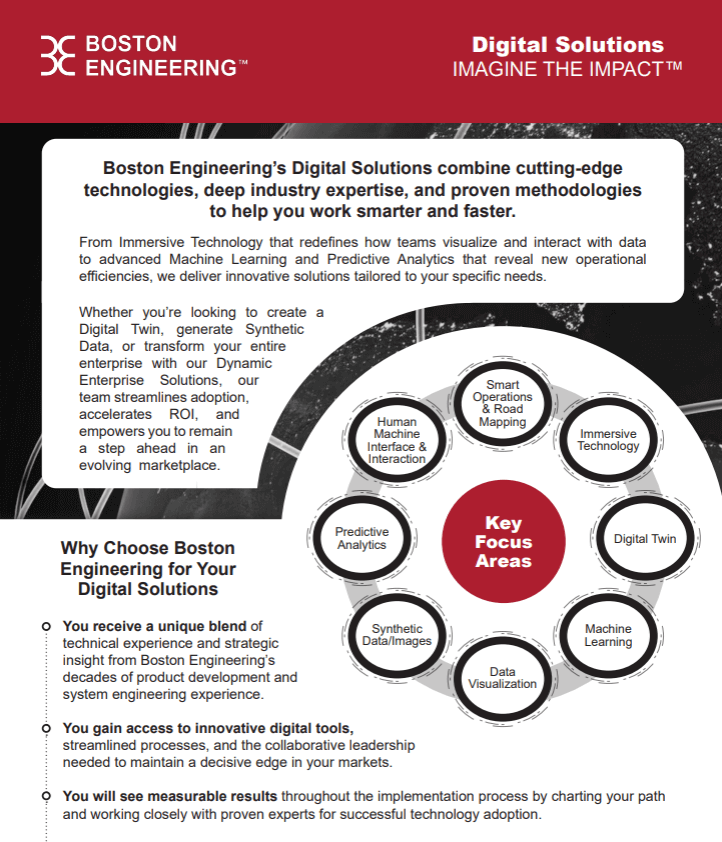

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Why Continuous Process Optimization Matters

- Operational Agility: Enables fast, informed decisions to adapt to changing conditions.

- Efficiency Gains: Reduces waste, lowers costs, and improves resource utilization.

- Performance Visibility: Offers real-time insights into how systems and processes are performing.

- Sustainable Growth: Supports long-term profitability and innovation by constantly identifying improvement opportunities.

Technologies Powering Continuous Process Optimization

1. Industrial Internet of Things (IIoT)

What It Is: IIoT connects physical assets through sensors and devices that collect real-time data across the operation.

Role in Optimization: IIoT provides the raw, real-time data needed to identify inefficiencies and monitor process performance continuously.

Example: A food production plant uses IIoT sensors on mixers and ovens to track energy use and output consistency. The data reveals overcooking trends on one line, prompting a quick fix that reduces energy use and improves product quality.

2. Artificial Intelligence & Machine Learning (AI/ML)

What It Is: AI/ML technologies process and learn from data patterns to automate insights, predictions, and optimizations.

Role in Optimization: These tools analyze historical and real-time data to fine-tune process variables, predict future performance, and recommend efficiency improvements.

Example: A packaging company uses AI to analyze line speed, error rates, and material usage. The system recommends minor adjustments to machine calibration, boosting throughput by 7% without additional capital investment.

3. Robotics & Automation

What It Is: Robotics and automation technologies execute tasks consistently and accurately, reducing human variability.

Role in Optimization: Automated systems continuously improve process speed, precision, and repeatability, especially in environments with fluctuating demand.

Example: A warehouse adjusts robot task assignments in real time based on order complexity and delivery deadlines, optimizing pick-and-pack cycles and improving daily order volume.

4. Digital Twin Technology

What It Is: Digital twins are virtual models of physical assets or systems that simulate real-world operations.

Role in Optimization: Digital twins enable scenario testing and predictive modeling, allowing teams to evaluate changes before implementing them in the real world.

Example: An energy company uses a digital twin of its processing facility to simulate different maintenance and production schedules. The result is a new schedule that balances uptime with energy efficiency.

5. Advanced Control Systems & Embedded Systems

What It Is: These systems automatically control machinery and processes based on live data inputs and algorithmic logic.

Role in Optimization: They make real-time adjustments to key variables such as temperature, flow rate, or torque to ensure optimal operating conditions.

Example: A plastics manufacturer uses embedded controllers to fine-tune extrusion speed and material blend ratios. This results in a 10% reduction in raw material usage without compromising quality.

6. Cybersecurity & Cloud Computing

What It Is: Cloud computing provides centralized access to data and analytics platforms, while cybersecurity ensures these systems remain protected and reliable.

Role in Optimization: Cloud platforms aggregate and analyze data across facilities, enabling enterprise-wide performance benchmarking and shared learnings. Cybersecurity ensures the data is secure and trustworthy.

Example: A multinational manufacturer uses a cloud-based operations dashboard to compare productivity across plants. The insights lead to standardizing a high-performing process observed at one site across the enterprise.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Conclusion: A Smarter, Safer Workforce Starts Here

Smart Operations redefine process improvement. With Continuous Process Optimization as a built-in outcome, organizations don’t just solve problems—they prevent them and capitalize on opportunities before competitors even recognize them.

By leveraging IIoT, AI/ML, Robotics & Automation, Digital Twins, Advanced Control Systems, and Secure Cloud Platforms, businesses can optimize every layer of their operations.

At Boston Engineering, we specialize in building the digital infrastructure and intelligence systems that make continuous optimization possible. Let’s work together to unlock more from your operations—every day, in every process.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!