Real-Time Quality Assurance: Enhancing Performance Through Smart Operations

In an era where speed, precision, and customer expectations are at an all-time high, companies cannot afford to treat quality as a downstream checkpoint.

Real-Time Quality Assurance is one of the most powerful outcomes of Smart Operations, offering manufacturers and product developers a way to proactively manage quality with intelligence and agility.

By leveraging advanced technologies, smart operations enable continuous monitoring, immediate feedback, and adaptive control of processes to ensure that quality issues are identified and addressed as they emerge. This not only reduces defects and rework but also enhances customer satisfaction, regulatory compliance, and profitability.

Continue reading below to learn more

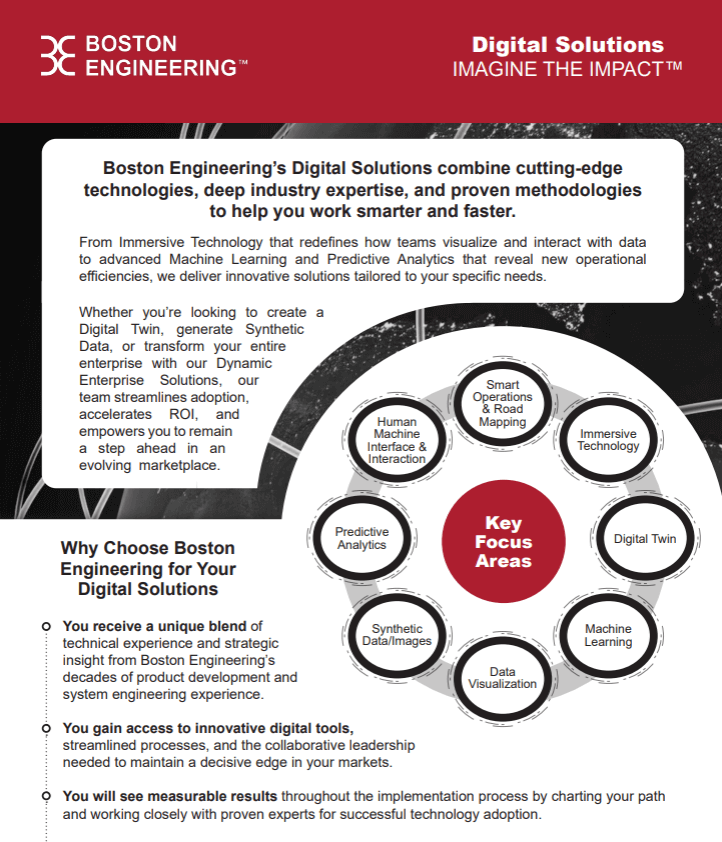

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Why Real-Time Quality Assurance Matters

- Customer Expectations: Markets demand increasingly higher quality and consistency.

- Cost of Poor Quality: Defects, rework, and recalls result in substantial financial and reputational damage.

- Speed to Market: Faster cycles require quality to be ensured in-process, not post-process.

- Regulatory Pressure: Industries like aerospace, medical devices, and food must document and verify quality in real time.

Smart Operations elevate quality control from reactive inspection to proactive assurance. Here’s how key technologies contribute to that transformation.

Technologies Enabling Real-Time Quality Assurance

1. Industrial Internet of Things (IIoT)

What It Is: IIoT uses networked sensors and devices to collect real-time data on machine performance, environmental conditions, and process metrics.

Role in Quality Assurance: IIoT provides continuous insight into critical quality variables, enabling immediate alerts when thresholds are exceeded.

Example: A beverage bottling plant uses IIoT sensors to monitor fill levels and cap torque. Deviations are detected instantly and resolved before defective products reach packaging.

2. Artificial Intelligence & Machine Learning (AI/ML)

What It Is: AI/ML analyzes complex datasets to detect patterns, make predictions, and suggest corrective actions.

Role in Quality Assurance: These technologies can identify subtle trends and anomalies that precede quality failures—even across multiple variables.

Example: An electronics manufacturer uses machine learning to analyze visual inspection data and test results. The system identifies a correlation between humidity levels and PCB defects, prompting preventive environmental controls.

3. Robotics & Automation

What It Is: Robotic systems and automated workflows enable precise, consistent execution of production tasks.

What It Is: Robotic systems and automated workflows enable precise, consistent execution of production tasks.

Role in Quality Assurance: Automation reduces human error and maintains consistent quality standards throughout the production process.

Example: In an automotive assembly line, robotic arms equipped with vision systems check weld integrity in real time, rejecting subpar joints before they progress downstream.

4. Digital Twin Technology

What It Is: Digital twins are virtual models of physical systems that simulate, monitor, and predict performance.

Role in Quality Assurance: They provide a predictive lens into how product quality might evolve based on process inputs, environmental factors, and machine behavior.

Example: A medical device manufacturer creates a digital twin of a catheter production line, enabling simulations that predict defect rates under different temperature and pressure settings.

5. Advanced Control Systems & Embedded Systems

What It Is: These systems provide precise real-time control of process parameters to maintain quality within specification.

Role in Quality Assurance: They automatically adjust operations based on data feedback to prevent drift or deviation.

Example: A plastics manufacturer uses embedded control systems to dynamically adjust extrusion temperature and speed to maintain uniform wall thickness.

6. Cybersecurity & Cloud Computing

What It Is: Cloud platforms offer centralized access to data and advanced analytics, while cybersecurity protects data integrity and system reliability.

Role in Quality Assurance: Cloud computing ensures seamless data sharing across systems and sites, while cybersecurity guarantees that quality data remains accurate and uncompromised.

Example: A global food producer uses a cloud-based quality monitoring system to aggregate data from multiple facilities. Real-time dashboards alert teams to potential deviations, and secure protocols ensure compliance with international food safety standards.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Conclusion: Embedding Quality into the Fabric of Operations

Real-Time Quality Assurance is no longer an option—it’s a competitive requirement. By integrating IIoT, AI/ML, Robotics & Automation, Digital Twins, Advanced Control Systems, and Cloud/Cybersecurity, Smart Operations enable businesses to detect and correct issues in the moment, not after the fact.

At Boston Engineering, we help organizations implement the intelligent infrastructure needed to make real-time quality assurance a core part of daily operations. Contact us to learn how you can move from reactive inspection to proactive quality control, and build a stronger, more consistent operation as a result.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!