Create a Seamless Operational Ecosystem with Interconnectivity & IoT Integration

Smart operations have become a cornerstone of competitive advantage.

One of the most transformative outcomes of implementing smart operations is the achievement of robust interconnectivity and IoT integration. This powerful combination creates an operational ecosystem where devices, systems, and people communicate seamlessly to drive unprecedented efficiency and innovation.

Continue reading below to learn more

The Boston Engineering Digital Solutions Portfolio

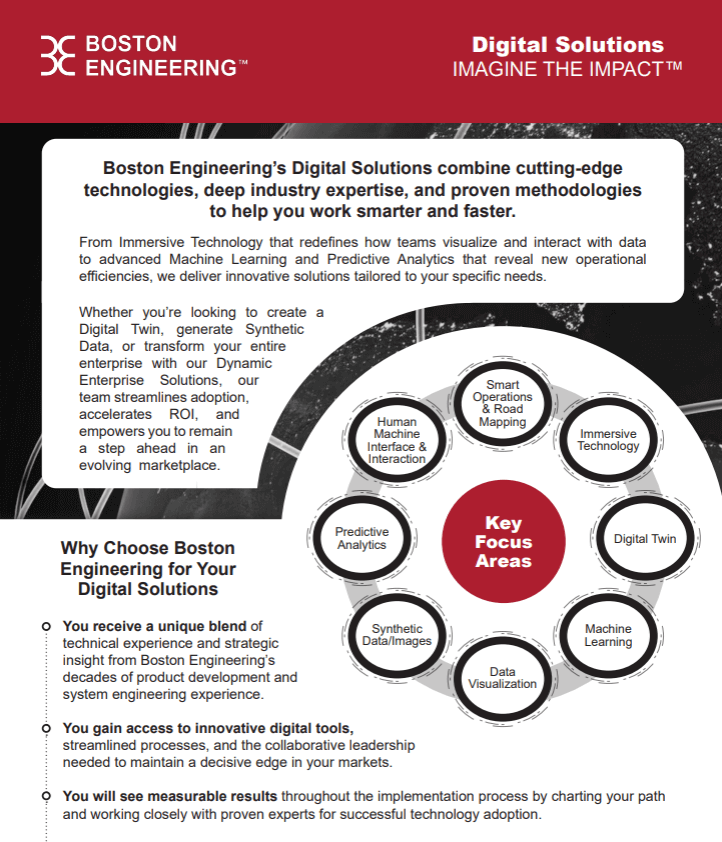

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

The Power of Connected Operations

Interconnectivity and IoT integration represent the nervous system of smart operations. By connecting previously isolated machines, systems, and processes through sensors and intelligent networks, businesses gain real-time visibility into their entire operational workflow. This integrated approach transforms how companies collect data, make decisions, and respond to changing conditions.

The Internet of Things (IoT) serves as the foundation of this interconnected framework, with smart devices and sensors continuously gathering operational data that flows through the organization. This creates an intelligent operational mesh where information moves freely between departments, eliminating silos and enabling more coordinated action.

Key Benefits for Business Performance

Real-Time Monitoring and Response

With IoT sensors deployed across operations, businesses can monitor performance metrics, environmental conditions, and equipment status in real time. For example, manufacturing companies can track machine temperatures, vibration patterns, and production speeds continuously, allowing them to detect anomalies before they cause breakdowns.

A food processing plant can implement IoT sensors throughout its production line, enabling immediate alerts when refrigeration temperatures deviate from optimal ranges. This real-time monitoring prevents potential spoilage and saves the company a significant amount in annual waste costs.

Predictive Maintenance

Traditional maintenance schedules often result in either premature part replacements or unexpected breakdowns. IoT integration enables predictive maintenance by analyzing equipment performance data to identify precisely when maintenance is needed.

For example, a transportation company equips its fleet with IoT sensors that monitor engine performance, fuel efficiency, and component wear. The predictive maintenance system can identify potential failures weeks before they would have occurred, reducing vehicle downtime and maintenance costs.

Enhanced Supply Chain Visibility

Interconnectivity extends beyond company walls to transform supply chain management. IoT-enabled tracking provides visibility into inventory levels, shipment locations, and supplier operations in real time.

A retail corporation can integrate IoT tracking across its entire supply chain, from manufacturers to distribution centers to stores. This interconnected system reduces inventory holding costs, decreases stockouts, and improves delivery time accuracy, significantly enhancing customer satisfaction.

Data-Driven Decision Making

The constant flow of operational data from interconnected devices creates a rich information foundation for more informed decision making. Advanced analytics applied to this data can reveal patterns and opportunities invisible to human observation alone.

A pharmaceutical manufacturer can implement an interconnected production system that generates comprehensive performance data across all processes. By analyzing this integrated data set, they identify previously undetected inefficiencies in their packaging line transitions, leading to process improvements that increased overall production capacity.

Implementation Strategies

Successfully implementing interconnectivity and IoT integration requires a strategic approach:

- Start with clear objectives: Define specific operational challenges that interconnectivity can address, rather than pursuing technology for its own sake.

- Build a scalable infrastructure: Implement a flexible IoT architecture that can accommodate future growth and additional devices.

- Prioritize cybersecurity: As connectivity increases, so do potential security vulnerabilities. Robust security protocols must be established from the beginning.

- Focus on integration: Ensure new IoT implementations can communicate with existing systems through appropriate middleware and integration platforms.

- Develop talent: Train your workforce to understand, maintain, and leverage the interconnected operational ecosystem.

The Future of Interconnected Operations

As IoT technology continues to advance, the potential for interconnectivity grows exponentially. Edge computing capabilities allow for faster processing of operational data directly at the source. 5G networks enable more devices to connect with greater reliability and lower latency. And AI-powered analytics increasingly extract deeper insights from the vast amounts of data generated by interconnected operations.

Forward-thinking businesses are already exploring how blockchain technology can enhance the security and transparency of their interconnected systems, and how digital twins can create virtual replicas of physical operations for more sophisticated simulation and optimization.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Conclusion

Interconnectivity and IoT integration represent far more than just technological advancement, they fundamentally transform how businesses operate. By creating a seamless flow of information across all operational areas, companies gain unprecedented visibility, control, and agility. In a business environment where adaptability and efficiency determine success, an interconnected operational ecosystem provides the foundation for sustainable competitive advantage.

Organizations that embrace this outcome of smart operations position themselves to respond more quickly to market changes, operate more efficiently, and deliver more value to customers. As we move deeper into the fourth industrial revolution, interconnectivity and IoT integration will increasingly separate industry leaders from those struggling to keep pace.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!