Maximizing Market Success with the Strategic Advantage of DFX

In this summary article, we see how taking proactive steps to integrate DFX into their strategies and processes, companies can position themselves for sustained success in a competitive marketplace.

Companies are constantly seeking ways to gain a competitive edge and enhance their market success. One powerful approach that consistently proves its worth is Design for X (DFX), a holistic strategy that encompasses various design principles tailored to specific objectives. From Design for Manufacturability (DFM) to Design for Usability (DFU), each facet of DFX contributes to achieving excellence in product development and market strategy.

By prioritizing efficiency, quality, user experience, and adaptability, companies can create products that not only meet but exceed customer expectations.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

DFX: A Strategic Imperative

DFX is not just a collection of design principles; it's a strategic imperative that shapes the entire product development process. By incorporating DFX into their strategies, companies can unlock numerous benefits that directly contribute to market success:

- Efficiency and Cost-effectiveness: Design for Manufacturability (DFM) optimizes manufacturing processes, reducing costs and streamlining production workflows. Design for Cost (DFC) ensures that products are not only innovative but also economically viable, enabling companies to offer competitive pricing without compromising quality.

- Quality and Reliability: Design for Reliability (DFR) focuses on creating products that consistently perform at the highest level over their lifespan. This proactive approach minimizes the risk of defects, enhances product reliability, and builds trust among customers, leading to increased brand reputation and customer loyalty.

- User Experience and Satisfaction: Design for Usability (DFU) prioritizes user-centric design, making products intuitive and easy to use. By understanding user needs and preferences, companies can create products that resonate with their target audience, leading to higher adoption rates, increased customer satisfaction, and positive word-of-mouth.

- Flexibility and Adaptability: Design for Modularity (DFMo) emphasizes modular design principles, allowing products to be easily adapted or upgraded to meet evolving customer needs. This flexibility enhances product longevity, reduces time-to-market for new iterations, and enables companies to stay ahead of the competition in a rapidly changing market landscape.

Learn more about Additive Manufacturing in the Design for X Space in this excerpt from

the Boston Engineering 2024 Technology Outlook. Written by Frank Silveira, Boston Engineering's Vice President of Engineering, this piece explores areas of continued growth in Additive Manufacturing to support Design for Assembly (DFA) and Design for Serviceability and Maintainability (Among Others). Read Now

Taking Advantage of DFX: Next Steps

For companies looking to harness the strategic advantage of DFX, the following steps are recommended:

- Assess Current Practices: Conduct a thorough assessment of current product development processes and identify areas where DFX principles can be integrated for maximum impact.

- Educate and Train Teams: Provide training and resources to teams involved in product development to ensure they understand the principles and importance of DFX. Encourage a culture of innovation and continuous improvement.

- Integrate DFX into Strategy: Incorporate DFX principles into the overall product development and market strategy. Align DFX objectives with broader business goals to ensure consistency and effectiveness.

- Iterate and Improve: Embrace an iterative approach to product development, continually seeking feedback from users and stakeholders to refine and enhance DFX implementations. Stay adaptable and responsive to changing market dynamics.

In conclusion: Incorporating Design for X (DFX) principles into product development and market strategy offers companies a strategic advantage that can significantly enhance their market success.

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

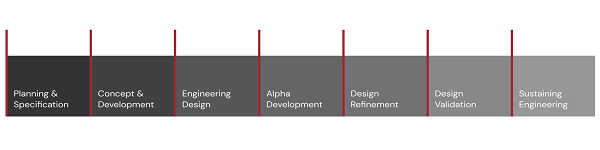

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!