Enhancing Market Success Through Design for Manufacturability

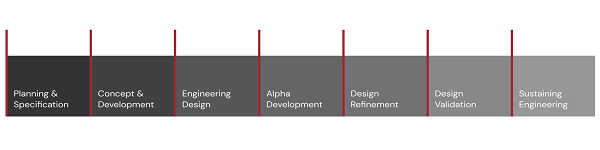

Design for Manufacturability (DFM) is a disciplined approach that focuses on optimizing the manufacturing processes from the early stages of product development.

The Power of DFM in Strategic Product Development:

DFM goes beyond the conventional scope of product design; it involves a comprehensive evaluation of various aspects that significantly impact a product's success in the marketplace. Boston Engineering recognizes the importance of incorporating DFM into its product development system, making it an integral part of their strategy. Let's delve into how DFM contributes to a smooth product launch and market success.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

-1.png?width=762&height=105&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Embracing DFM as a core element of product development is not just a technical consideration but a strategic imperative for companies aiming to thrive.

Incorporating Design for Manufacturability into a broader strategic approach is a game-changer for companies seeking sustained success in the competitive market. DFM goes beyond the conventional scope of product design; it involves a comprehensive evaluation of various aspects that significantly impact a product's success in the marketplace.

Here are ways DFM contributes to a smooth product launch and market success:

- Efficient Manufacturing Processes: DFM is centered around optimizing the manufacturability of a product. By considering manufacturing constraints early in the design phase, companies can streamline production processes, reduce production costs, and enhance overall efficiency. This approach allows for the creation of products that not only meet design specifications but are also feasible to manufacture at scale.

- Reliability and Quality Assurance: Ensuring product reliability is a key factor in gaining customer trust and loyalty. DFM takes into account factors such as materials selection and assembly processes to enhance product reliability. By addressing potential issues before they arise, companies can minimize the risk of defects and improve overall product quality.

- Cost-effectiveness: Managing costs is a critical aspect of any successful product strategy. DFM helps identify opportunities for cost reduction by optimizing materials usage, minimizing waste, and streamlining production processes. This, in turn, allows companies to offer competitive pricing in the market without compromising on product quality.

- Regulatory Compliance: Navigating industry standards and government regulations is a complex task. DFM includes considerations for compliance from the outset, ensuring that products meet all necessary standards. This proactive approach not only facilitates a smoother market entry but also mitigates the risk of costly redesigns to meet regulatory requirements.

- Market Responsiveness: The ability to quickly bring a product to market is a crucial competitive advantage. DFM expedites the product development cycle by reducing iterations and minimizing unexpected challenges during manufacturing. Companies employing DFM can respond more rapidly to market demands, gaining an edge over competitors.

Learn more about Additive Manufacturing in the Design for X Space in this excerpt from

the Boston Engineering 2024 Technology Outlook. Written by Frank Silveira, Boston Engineering's Vice President of Engineering, this piece explores areas of continued growth in Additive Manufacturing to support Design for Assembly (DFA) and Design for Serviceability and Maintainability (Among Others). Read Now

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!