Learning From DFX: Anticipating and Preventing Future Challenges

DFX teaches that understanding the intricacies of the design process is paramount to success. However, there are often costly lessons learned along the way. One such lesson revolves around the misconception of repurposing breadboards or prototypes for mass production without due consideration.

As experienced Design for X (DFX) Subject Matter Experts (SME), we've witnessed firsthand the pitfalls of this approach. While breadboards serve a crucial role in testing core technologies, attempting to transition them directly into end products can spell disaster. This practice often leads to inefficiencies, increased costs, and compromised product integrity.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

Learning from Costly Design Lessons: Anticipating and Preventing Future Challenges

(continued from above)

To prevent such setbacks, it's imperative to maintain a clear vision of the end goal from the project's outset. Understanding the distinction between technology exploration and product development is key. While breadboards aid in refining core technologies, they should not dictate the design of the final product.

Instead, a proactive approach involves designing the end product with manufacturing efficiency in mind. By considering factors such as production quantity and optimal manufacturing processes early on, potential roadblocks can be mitigated. This strategy enables seamless progression from design to prototyping, streamlining the development process and ultimately reducing costs.

In essence, the key takeaway is simple: embrace a forward-thinking mindset that prioritizes efficiency and foresight. By learning from past mistakes and embracing DFX principles, designers can anticipate and prevent costly challenges, ensuring smoother transitions from concept to production.

Interested in providing your product development team with DFX skills? Learn More about our Applied DFX process and development workshops.

Learn more about Additive Manufacturing in the Design for X Space in this excerpt from

the Boston Engineering 2024 Technology Outlook. Written by Frank Silveira, Boston Engineering's Vice President of Engineering, this piece explores areas of continued growth in Additive Manufacturing to support Design for Assembly (DFA) and Design for Serviceability and Maintainability (Among Others). Read Now

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

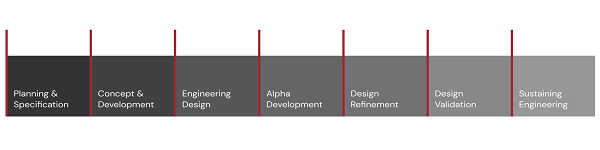

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!