Building Sustained Customer Loyalty: Leveraging Design for X (DFX) Methodologies in New Product Development

Customer loyalty is crucial for long-term business success. By applying Design for X (DFX) methodologies, companies can develop products that not only meet customer needs but also foster strong, lasting relationships. Here’s how different DFX methodologies contribute to sustained customer loyalty.

Creating sustained customer loyalty is a key objective in product development, and DFX methodologies provide a structured approach to achieving this goal.

Working with DFX experts ensures that these methodologies are effectively applied, resulting in high-quality products that build strong, lasting relationships with customers.

Here’s how different DFX methodologies can be employed to accelerate time to market in new product development:

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

Leveraging Design for X (DFX) Methodologies to accelerate time to market in New Product Development:

(continued from above)

1. Design for Manufacturability (DFM)How DFM Fosters Customer Loyalty: DFM ensures that products are consistently manufactured to high standards, which helps build customer trust in the brand. A product that is reliably produced with minimal defects encourages repeat purchases and positive word-of-mouth.

Application:

- Consistency in Quality: By designing products that are easy to manufacture with consistent quality, DFM minimizes variations that could lead to defective products. This reliability builds customer confidence and loyalty.

- Meeting Delivery Expectations: Efficient manufacturing processes facilitated by DFM help ensure that products are delivered on time, meeting customer expectations and enhancing satisfaction.

Example: A home appliance company designs a new coffee maker with DFM principles, ensuring that every unit meets high-quality standards. Customers who receive a consistently reliable product are more likely to remain loyal to the brand.

How DFA Fosters Customer Loyalty: DFA simplifies the assembly process, leading to fewer assembly errors and higher product quality. Customers appreciate products that are well-built and free from defects, which strengthens their loyalty to the brand.

Application:

- Enhanced Product Quality: By reducing the complexity of assembly, DFA minimizes the risk of assembly errors that could compromise product quality, leading to higher customer satisfaction and loyalty.

- Longer Product Lifespan: Well-assembled products are more durable and have fewer issues, which encourages customers to stay loyal to a brand known for quality craftsmanship.

Example: A tech company designing a new laptop uses DFA to simplify the internal assembly, reducing the risk of loose connections or other issues. This attention to detail results in a more reliable product, fostering customer loyalty through consistent performance.

3. Design for Cost (DFC)How DFC Fosters Customer Loyalty: DFC ensures that products are priced competitively without sacrificing quality. By offering high-value products at an attractive price, companies can appeal to cost-conscious customers, encouraging repeat business and brand loyalty.

Application:

- Value for Money: DFC helps companies design products that deliver great performance and features at a reasonable cost, which appeals to customers looking for value, driving loyalty.

- Affordability Without Compromise: By managing costs effectively, DFC allows companies to offer premium features at a lower price point, making high-quality products accessible to more customers and enhancing brand loyalty.

Example: A consumer electronics brand designs a new budget-friendly smartphone using DFC principles, offering premium features at a lower price. Customers who feel they’re getting great value are more likely to remain loyal to the brand for future purchases.

4. Design for Testability (DFT)How DFT Fosters Customer Loyalty: DFT ensures that products are thoroughly tested before reaching customers, reducing the likelihood of defects. High product reliability leads to fewer returns and repairs, which strengthens customer trust and loyalty.

Application:

- Reduced Defects: DFT allows for comprehensive testing, ensuring that only high-quality, defect-free products reach customers, leading to a more satisfying user experience and increased loyalty.

- Confidence in the Brand: Customers who know that a brand rigorously tests its products before release are more likely to trust the brand and remain loyal over time.

Example: An automotive company uses DFT in developing a new electric vehicle, ensuring that all components are thoroughly tested for reliability. This approach results in fewer issues for customers, who then develop a strong sense of loyalty to the brand.

Interested in providing your product development team with DFX skills? Learn More about our Applied DFX process and development workshops.

(continued from above)

5. Design for Reliability (DFR)How DFR Fosters Customer Loyalty: DFR ensures that products perform consistently and reliably over time, which is key to maintaining customer satisfaction. Products that stand the test of time encourage repeat purchases and brand advocacy.

Application:

- Long-Term Satisfaction: DFR helps create products that customers can rely on, leading to long-term satisfaction and loyalty. Reliable products reduce the frustration of frequent repairs or replacements.

- Brand Reputation: A brand known for reliable products builds a strong reputation, which encourages customer loyalty and attracts new customers through positive word-of-mouth.

Example: A power tools manufacturer uses DFR to ensure that their new drill is durable and reliable under heavy use. Customers who experience the reliability of the product are more likely to stay loyal to the brand and recommend it to others.

6. Design for Serviceability/Maintainability (DFS)

How DFS Fosters Customer Loyalty: DFS focuses on making products easy to service and maintain, which enhances the customer experience. When customers can easily maintain and repair their products, they are more likely to remain loyal to the brand.

Application:

- Ease of Maintenance: Products designed for easy maintenance reduce the hassle for customers, leading to higher satisfaction and a greater likelihood of repeat purchases.

- Extended Product Life: DFS ensures that products are easy to repair, extending their lifespan and increasing customer loyalty as they continue to use and trust the brand’s products.

Example: A home appliance company designs a new refrigerator with DFS principles, making it easy for customers to perform routine maintenance and repairs. This user-friendly approach helps build long-term loyalty as customers appreciate the product’s longevity and ease of use.

How DFU Fosters Customer Loyalty: DFU ensures that products are intuitive and easy to use, which enhances the customer experience and encourages repeat business. Products that are user-friendly create positive experiences that customers want to repeat.

Application:

- Enhanced User Experience: DFU focuses on creating products that are easy to use, leading to higher customer satisfaction and loyalty as customers enjoy using the product.

- Reduced Learning Curve: By designing intuitive products, DFU reduces the time customers need to learn how to use a product, making them more likely to stick with the brand.

Example: A software company designs a new app with DFU principles, ensuring that the interface is intuitive and easy to navigate. Customers who find the app easy to use are more likely to continue using it and remain loyal to the brand.

8. Design for Modularity (DFMo)

How DFMo Fosters Customer Loyalty: DFMo allows for products to be easily customized and upgraded, which can lead to sustained customer loyalty as customers can adapt the product to their changing needs over time.

Application:

- Customization Options: DFMo enables customers to personalize their products, creating a sense of ownership and loyalty as they invest in a product that fits their unique preferences.

- Upgradability: By designing products that can be easily upgraded, DFMo ensures that customers can keep their products up-to-date without needing to purchase entirely new ones, encouraging long-term loyalty.

Example: A tech company designs a modular smart home system with DFMo, allowing customers to easily upgrade or customize their setup as their needs evolve. This flexibility fosters loyalty as customers can continuously improve their system without switching to a different brand.

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

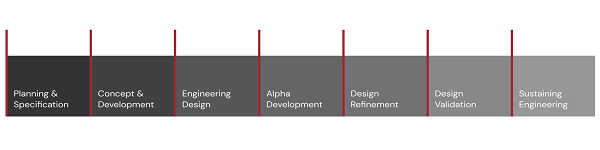

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!