Automation & Intelligent Control: The Foundation of Smart Operations

Organizations are seeking ways to remain competitive, resilient, and agile.

Smart Operations—the integration of advanced technologies, connected systems, and intelligent analytics into manufacturing and operational processes—offers a powerful solution through Automation & Intelligent Control systems that transform traditional manufacturing and operational environments into responsive, self-optimizing ecosystems.

Why Automation & Intelligent Control Matter Now

The business imperative for advanced automation and intelligent control has never been stronger:

- Labor Challenges: Skilled workforce shortages across industries create pressure to automate routine tasks

- Market Volatility: Rapidly changing customer demands require flexible, adaptable production systems

- Competitive Pressure: Global competition drives the need for continuous efficiency and quality improvements

- Supply Chain Disruptions: Recent disruptions highlight the need for responsive, adaptable operations

- Sustainability Requirements: Growing pressure to reduce energy and resource consumption

Smart Operations addresses these challenges by creating systems that not only automate routine tasks but continuously learn, adapt, and optimize performance with minimal human intervention.

Continue reading below to learn more

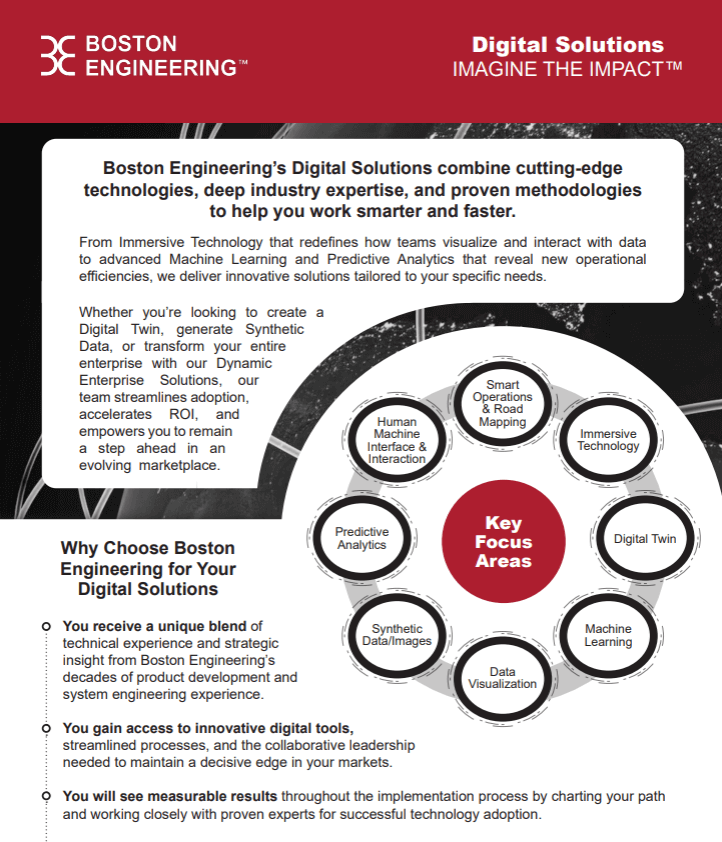

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Key Technologies Enabling Automation & Intelligent Control

The transformation toward intelligent automation is powered by several interconnected technologies. Let's explore how each contributes to this critical business outcome:

Industrial Internet of Things (IIoT)

How It Enables Automation & Control: IIoT creates the sensory foundation of intelligent automation by connecting physical equipment, environmental conditions, and operational processes through networked sensors and devices. This connectivity provides the real-time data streams necessary for dynamic control decisions and creates the communication infrastructure that allows automated systems to coordinate their actions.

Technology in Action: Imagine a pharmaceutical manufacturing operation where IIoT sensors continuously monitor environmental conditions (temperature, humidity, particulate levels), equipment performance parameters (pressure, flow rates, vibration), and process variables (mixing speeds, material properties). These interconnected sensors would enable automated environmental controls to maintain exact conditions required for product quality, trigger predictive maintenance activities before equipment failures, and create comprehensive digital documentation for regulatory compliance—all with minimal human intervention.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Artificial Intelligence & Machine Learning (AI/ML)

How It Enables Automation & Control: AI/ML systems transform automation from executing fixed instructions to making intelligent decisions based on current conditions, historical patterns, and predictive models. These technologies enable systems to identify complex patterns, optimize across multiple variables simultaneously, handle exceptions without human intervention, and continuously improve performance through experience.

Technology in Action: Consider a chemical processing facility implementing ML-powered process controls that learn the complex relationships between numerous variables affecting product quality. The system would analyze thousands of historical production runs to identify optimal operating parameters, detect subtle early warning signs of quality deviations, and automatically adjust process conditions to maintain consistent output despite variations in raw materials or environmental conditions. Over time, the system would continuously refine its control strategies, achieving levels of process optimization beyond what human operators could develop manually.

How It Enables Automation & Control: Modern robotics extends automation beyond rigid, programmed movements to flexible, adaptive physical interactions with the environment. Advanced robotic systems incorporate sophisticated sensors, embedded intelligence, and natural programming interfaces that expand automation into tasks previously considered too complex or variable for machines.

Technology in Action: Imagine a consumer electronics assembly operation deploying collaborative robots with advanced vision systems and force-sensing capabilities. These robots would work alongside human operators, handling repetitive precision tasks while adapting to product variations without reprogramming. When new product variants are introduced, operators could simply demonstrate the assembly procedure, which the robots would learn and refine. The system would automatically distribute work between humans and robots based on the specific requirements of each task, optimizing throughput while ensuring quality.

Digital Twin Technology

How It Enables Automation & Control: Digital twins serve as virtual counterparts to physical systems, enabling simulation, testing, and optimization of automation strategies before implementation. By mirroring real-world conditions and behaviors, digital twins provide a safe environment for developing control algorithms, predicting system responses, and validating automated decision-making logic.

Technology in Action: Consider a manufacturing facility creating digital twins of its production lines to develop and test advanced control algorithms. Engineers would use these virtual environments to simulate thousands of production scenarios, identifying optimal control parameters and potential failure modes without disrupting actual production. Once validated in the digital twin, control strategies would be deployed to the physical systems with confidence. During operation, real-time comparisons between digital twin predictions and actual performance would enable continuous refinement of both the virtual model and the control algorithms.

Advanced Control Systems & Embedded Systems

How It Enables Automation & Control: Advanced control systems move beyond simple PID (Proportional-Integral-Derivative) control to incorporate complex models, adaptive algorithms, and distributed intelligence. Embedded systems distribute computational capabilities throughout the operational environment, enabling local intelligence, real-time decision-making, and resilient control architectures.

Technology in Action: Imagine a food processing operation implementing advanced model predictive control (MPC) systems with distributed embedded intelligence throughout the production process. These systems would continuously adjust multiple process variables to optimize for competing objectives like throughput, energy efficiency, and product consistency. Embedded controllers at each process stage would make local decisions while coordinating with the broader system, creating resilient operations that maintain performance even if communication to central systems is temporarily disrupted. When product specifications change, the control parameters would automatically adjust to maintain optimal performance without manual reconfiguration.

Cybersecurity & Cloud Computing

How It Enables Automation & Control: Cybersecurity provides the trust foundation essential for automated systems, ensuring that control commands and data are protected from manipulation. Cloud computing delivers the scalable computational resources and enterprise-wide visibility needed for complex automation coordination, while enabling remotely-operated systems with appropriate security safeguards.

Technology in Action: Consider a multi-site manufacturing organization implementing a secure cloud-based control architecture with comprehensive cybersecurity protections. This system would centralize operational data while distributing control functions appropriately between cloud and local systems. Engineers could develop and deploy control strategies across multiple facilities from a central location, ensuring consistency while adapting to local requirements. The cybersecurity framework would authenticate all control commands, monitor for anomalous behavior, and isolate critical systems from potential threats—creating a trusted foundation for autonomous operations. During equipment trials or maintenance, specialists could securely access and operate systems remotely, providing expert oversight without travel requirements.

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

The Synergistic Power of Integrated Technologies

While each technology delivers significant value individually, their true transformative power emerges when implemented as an integrated ecosystem. Consider how these technologies work together in a comprehensive Smart Operations implementation:

- IIoT sensors collect real-time data from equipment and processes

- AI/ML systems analyze this data to identify optimization opportunities

- Digital twins simulate and validate potential control strategies

- Advanced control systems implement optimized parameters across operations

- Robotic systems execute physical tasks with precision and flexibility

- Cybersecurity ensures the integrity of the entire system

- Cloud computing coordinates activities across the enterprise

This integration creates a continuous improvement cycle where physical systems inform digital models, which then optimize control strategies that are implemented back in the physical world—all while maintaining security and trust.

The Evolution Toward Autonomous Operations

The journey toward fully autonomous operations typically progresses through several stages:

- Connected Operations: Systems generate data but require human decision-making

- Assisted Operations: Systems recommend actions for human approval

- Supervised Autonomy: Systems act independently with human oversight

- Full Autonomy: Systems perform extended operations with minimal intervention

Most organizations implement a hybrid approach, with different processes operating at different autonomy levels based on complexity, criticality, and maturity of available technologies.

Building Your Automation & Intelligent Control Strategy

Organizations seeking to leverage these technologies should consider a structured approach:

- Assessment: Identify high-value opportunities and current capability gaps

- Prioritization: Focus on applications with clear ROI and manageable complexity

- Foundational Implementation: Establish connectivity and data infrastructure

- Capability Development: Build expertise through targeted pilot projects

- Scaled Deployment: Expand successful implementations across operations

- Continuous Advancement: Regularly reassess and incorporate emerging technologies

Conclusion

Automation & Intelligent Control represents a transformative capability unlocked through Smart Operations. By integrating advanced physical systems with sophisticated digital intelligence, organizations create operations that are simultaneously more productive, consistent, flexible, and resilient.

The competitive advantages extend beyond traditional efficiency metrics to encompass strategic dimensions like responsiveness, innovation speed, and adaptation to unpredictable events. In a business environment characterized by constant change and disruption, these capabilities aren't just performance enhancers—they're essential foundations for sustained competitive advantage.

Organizations that embrace this transformation position themselves not merely to excel in current markets but to continuously evolve as technology, customer expectations, and competitive landscapes shift in the future.

Considering your own journey toward connected, data-driven operations? Partner with experts who understand both the technology landscape and the strategic business implications of Smart Operations implementation.

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!