Sustainability & Resilience: Building Future-Proof Operations Through Smart Technologies

The economy faces increasing environmental pressures, supply chain disruptions, and market volatility, and businesses face two imperative challenges: creating operations that minimize environmental impact while withstanding unexpected shocks.

Smart Operations deliver the critical outcome of sustainability and resilience—providing companies with both the environmental responsibility customers demand and the operational stability shareholders require.

Why Sustainability & Resilience Matter Now

The business case for sustainability and resilience has never been stronger:

Environmental imperatives are intensifying through regulation, investor pressure, and consumer expectations. Companies must reduce resource consumption, minimize waste, and decrease carbon footprints not just for ethical reasons but for their very license to operate.

Operational resilience has become non-negotiable as global disruptions increase in frequency and impact. From pandemic-driven shortages to extreme weather events, operations must withstand unexpected shocks while maintaining business continuity.

The companies that thrive in this new reality will be those that leverage smart operations technologies to build sustainable, resilient business models.

Let's explore how specific technologies create these essential outcomes.

Continue reading below to learn more

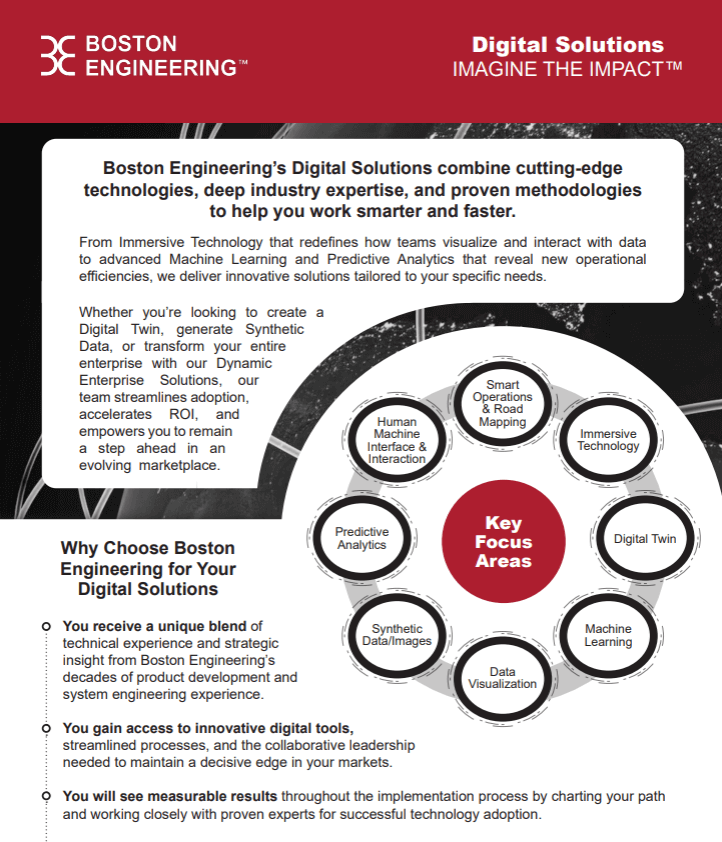

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

- Industrial Internet of Things (IIoT)

Technology Overview

IIoT creates networks of connected sensors, devices, and machines that continuously generate and share operational data. This connectivity provides unprecedented visibility into resource consumption, operational conditions, and potential failure points.

How It Enables Sustainability & Resilience

IIoT transforms sustainability and resilience by:

- Providing real-time monitoring of energy and resource consumption

- Identifying resource waste and inefficiencies throughout operations

- Detecting equipment anomalies before they lead to failures

- Creating transparency across operations and supply chains

Illustrative Example

Consider a paper manufacturing company that deploys IIoT sensors throughout its water-intensive production facility. The sensors continuously monitor water usage, quality parameters, and treatment processes while tracking energy consumption across all equipment. The system identifies previously undetected leaks and inefficient water recycling processes, enabling targeted improvements that reduce water consumption and energy usage through the facility.

If regional water restrictions are implemented during a drought, the company's enhanced visibility would allow it to quickly adjust processes to meet new constraints while maintaining production. The detailed monitoring system also simplifies regulatory compliance reporting, providing verifiable sustainability metrics for increasingly demanding customers and investors.

Contact us to talk about similar opportunities in your operations

- Artificial Intelligence & Machine Learning (AI/ML)

Technology Overview

AI/ML systems analyze vast datasets to identify patterns, predict outcomes, and optimize processes beyond human capabilities. These technologies continuously learn and improve, making operations progressively more efficient and resilient over time.

How It Enables Sustainability & Resilience

AI/ML enhances sustainability and resilience through:

- Optimizing resource utilization across complex operations

- Predicting potential equipment failures before they occur

- Modeling and anticipating supply chain disruptions

- Creating adaptive responses to changing conditions

Illustrative Example

Consider a consumer packaged goods manufacturer that implements AI-powered energy management across its production facilities. The system analyzes thousands of variables affecting energy consumption—including production schedules, equipment status, weather conditions, and energy market pricing. It continuously optimizes operations to minimize both energy usage and costs while maintaining production targets.

The AI system identifies energy-intensive processes that could be shifted to off-peak hours, equipment settings that waste energy, and opportunities to leverage renewable energy sources. This optimization then reduces both energy consumption and carbon emissions.

Additionally, the predictive maintenance capabilities of the new system can prevent major equipment failures, avoiding both production disruptions and the environmental impact of emergency repairs and replacement parts. When unusual weather patterns create energy supply constraints, the system automatically adjusts production schedules to maintain operations while reducing peak demand, demonstrating enhanced resilience while supporting grid stability.

Contact us to talk about similar opportunities in your operations

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

- Robotics & Automation

Technology Overview

Modern robotics and automation systems replace manual processes with precision machinery and programmed workflows. Today's advanced systems offer unprecedented flexibility, safety, and integration capabilities compared to legacy automation.

How It Enables Sustainability & Resilience

Robotics and automation contribute to sustainability and resilience by:

- Optimizing material usage and reducing waste through precision

- Decreasing energy consumption through efficient motion and process control

- Maintaining operational continuity during labor shortages or disruptions

- Enabling consistent quality and compliance with environmental standards

Illustrative Example

Suppose a precision electronics manufacturer deploys collaborative robots and advanced automation systems throughout its assembly operations. The robotic systems applies materials with microscopic precision, reducing waste of expensive and environmentally sensitive components vs traditional manual processes. Energy-efficient servo motors and intelligent power management also reduces the energy required for assembly operations.

Further, the automated systems allows the facility to maintain a high percentage of normal production with minimal on-site staff. The robotic systems also eliminate human exposure to potentially harmful solvents and adhesives, improving worker safety while reducing hazardous waste generation.

Finally, the company programs the robots to automatically adjust processes based on material variations, significantly improving yield rates and reducing the resources wasted on defective products. This adaptive capability will prove essential if supply chain disruptions force the use of alternative components with slightly different properties.

- Digital Twin Technology

Technology Overview

Digital twin technology creates dynamic virtual replicas of physical assets, processes, or entire operations. These digital models simulate real-world conditions and behaviors, enabling scenario testing and optimization without disrupting actual operations.

How It Enables Sustainability & Resilience

Digital twins enhance sustainability and resilience through:

- Virtual scenario testing to identify optimal resource-efficient processes

- Simulating disruption scenarios and developing response strategies

- Optimizing existing operations without wasteful physical trial-and-error

- Providing a virtual environment to train staff on handling unusual conditions

Illustrative Example

Imagine a chemical processing company creates a comprehensive digital twin of its production facility, modeling all equipment, resources flows, and interdependencies. Engineers use this virtual environment to simulate process modifications aimed at reducing natural gas consumption and greenhouse gas emissions. The digital twin identifies optimization opportunities that would have been too risky to test in the physical plant, ultimately leading to process changes that reduce both emissions and energy costs.

If a major hurricane threatens the region, management can use the digital twin to simulate various damage scenarios and develop continuity plans. The simulations identify critical vulnerabilities in utility connections, which were reinforced before the storm. When partial damage does occur, the digital twin helps operators reconfigure the remaining equipment to maintain essential production capacity while repairs are completed.

Contact us to talk about similar opportunities in your operations

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

- Advanced Control Systems & Embedded Systems

Technology Overview

Advanced control systems coordinate complex operations through sophisticated algorithms and distributed intelligence. Embedded systems—computing devices integrated directly into equipment—enable local processing and control, making equipment smarter and more adaptable.

How It Enables Sustainability & Resilience

These technologies enhance sustainability and resilience by:

- Optimizing process parameters in real-time to minimize resource use

- Adapting operations to changing conditions automatically

- Providing rapid fault detection and isolation to prevent cascading failures

- Enabling fine-grained control over energy-intensive processes

Illustrative Example

What if a food processing company implements advanced control systems with embedded intelligence throughout its energy-intensive cooking and freezing operations? The system continuously monitors product temperature, moisture content, and energy usage, making microsecond adjustments to maintain optimal conditions with minimal resource consumption.

The embedded systems in refrigeration equipment detects early signs of refrigerant leaks—a major source of greenhouse gas emissions—and automatically isolates affected circuits while alerting maintenance. This capability reduces refrigerant losses while preventing complete system failures that would result in product loss.

The distributed intelligence of the embedded systems also creates a natural resilience—if communications with central systems are lost during a network outage, local controllers continue to optimize individual processes independently until connectivity is restored.

Contact us to talk about similar opportunities in your operations

- Cybersecurity & Cloud Computing

-

Technology Overview

Modern cybersecurity frameworks protect connected operations from digital threats. Cloud computing provides scalable computational resources, data storage, and software services accessed via the internet rather than on-premises infrastructure.

How It Enables Sustainability & Resilience

This technological pairing supports sustainability and resilience by:

- Reducing physical infrastructure and associated energy consumption

- Enabling remote operations that decrease commuting and facility requirements

- Providing robust backup and disaster recovery capabilities

- Protecting critical operational systems from disruption via cyber attacks

Illustrative Example

Suppose a midsize manufacturing company transitioned from energy-intensive on-premises data centers to cloud-based operational systems protected by comprehensive cybersecurity protocols. The migration reduces energy consumption for computing as the cloud provider's optimized data centers operate at significantly greater efficiency than the company's legacy systems.

The cloud infrastructure enables effective remote work during both travel restrictions and severe weather events, maintaining business continuity while reducing commuting emissions. Were ransomware attacks to hit competitors, the company's robust cybersecurity framework successfully blocks similar attempts, preventing the operational disruptions and recovery costs experienced by others in the industry.

The cloud platform also enables more effective resource planning across multiple facilities, allowing the company to optimize production scheduling based on the different energy sources available at each location. This capability reduces the company's overall carbon footprint by shifting energy-intensive processes to locations and times when renewable energy was most available, without sacrificing production targets.

Contact us to talk about similar opportunities in your operations

Building Your Sustainable, Resilient Foundation

Implementing these technologies requires a strategic approach focused on tangible business outcomes rather than technology for its own sake. Organizations should:

- Assess current vulnerabilities and impacts: Identify where operational disruptions are most likely and where environmental impacts are greatest

- Start with high-ROI opportunities: Focus initial efforts where sustainability and resilience improvements deliver clear business value

- Build with integration in mind: Ensure technologies work together through standardized platforms and data protocols

- Develop both technology and human capabilities: Train people to leverage these new systems effectively

- Measure and report progress: Establish clear metrics for both sustainability and resilience improvements

Conclusion

Sustainability and resilience have evolved from peripheral concerns to central business imperatives. Smart operations technologies provide the foundation companies need to reduce environmental impact while building operations that withstand disruption.

The technologies we've explored—IIoT, AI/ML, Robotics, Digital Twins, Advanced Control Systems, and Cybersecurity/Cloud Computing—each contribute uniquely to creating sustainable, resilient operations. Together, they enable businesses to meet increasingly stringent environmental expectations while maintaining continuity through unexpected challenges.

As you consider your smart operations journey, focus on how these technologies can simultaneously advance your sustainability goals and strengthen operational resilience. The resulting operations won't just be more responsible and robust—they'll be fundamentally more competitive in a business environment where adaptability to both environmental imperatives and operational disruptions determines long-term success.

Partner with Boston Engineering to develop your roadmap for connectivity and data-driven decision-making. Our multidisciplinary expertise ensures seamless integration across technologies and systems, delivering transformative results for your operations.

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!