Scaling Manufacturing Automation: Engineering Robust Systems That Grow with Demand

Manufacturing automation is essential for quality, cost control, and throughput.

Many manufacturers struggle when initial automation solutions can’t adapt to evolving product lines or fluctuating production volumes.

That’s where scalable robotics—systems engineered to grow and change—can unlock enduring value. In this blog, we cover what scalable manufacturing automation looks like, why it’s so important, and how Boston Engineering helps manufacturers stay both agile and efficient.

Continue reading below to learn more

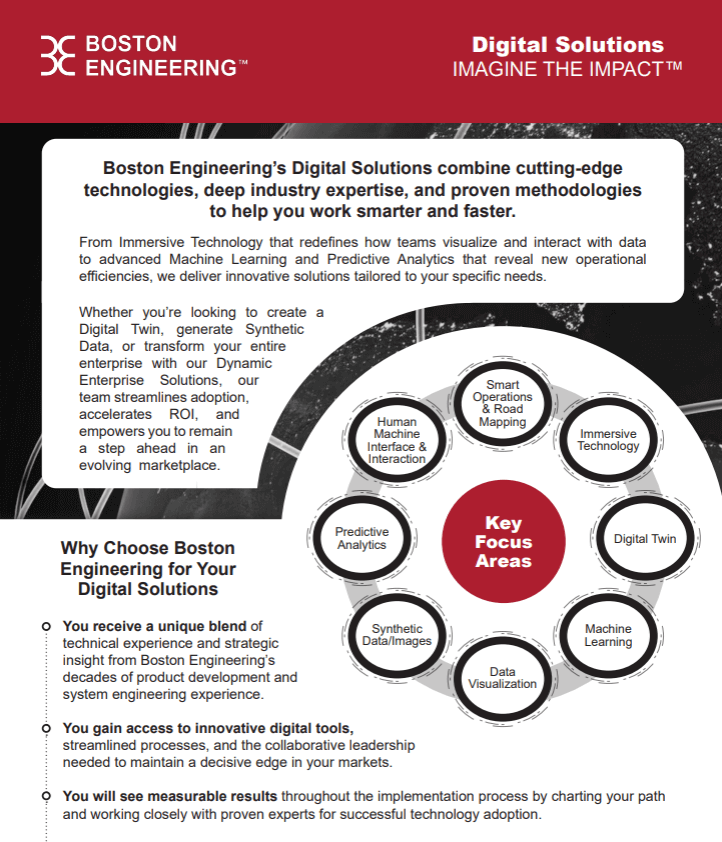

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Understanding Scalability in Production Environments

In manufacturing, scalability goes beyond simply adding more machines. It means designing robotic systems that can:

- Handle higher production volumes

- Switch between different tasks or models

- Integrate new production technologies

- Coordinate across distributed robotic assets

This flexibility allows manufacturers to adapt to market demands without system lock-in or costly redesigns.

Manufacturing Pain Points Made Solvable Through Scalability

1. Product Variation and Customization

Today’s customers demand variety. Scalable systems can drive flexible automation that switches between product lines with minimal downtime.

2. Rapid Volume Shifts

Unexpected demand spikes or new contracts can overwhelm fixed systems. Scalable automation lets you incrementally increase robotic resources to maintain throughput.

3. Technology Obsolescence

Manufacturing technologies evolve quickly. Scalable systems are built on modular and open frameworks that make adopting new capabilities seamless rather than disruptive.

Technical Pillars of Scalability in Automation

Flexible Robotics Architecture

Scalability starts with strong architectural design—systems must be built from the ground up to accept new robots, controllers, and capabilities without breaking existing workflows.

Open Frameworks and Standards

Using industry-standard frameworks (such as ROS2) ensures that systems can integrate future software components and tools as they emerge.

Orchestrated Fleet Intelligence

Coordinating multiple robots intelligently ensures that performance improves, not degrades, as you scale up.

A Scalable Manufacturing Use Case: Collaborative Robots (Cobots)

Cobots are a powerful example of scalability in manufacturing. Unlike purpose-built robots that perform a single task, cobots can be:

Cobots are a powerful example of scalability in manufacturing. Unlike purpose-built robots that perform a single task, cobots can be:

- redeployed across production lines,

- programmed for new stations,

- and integrated into fleet-wide control systems.

This makes them especially effective in environments with evolving product lines.

Business Benefits of Scalable Manufacturing Automation

Scalable systems deliver measurable advantages:

- Lower lifecycle costs by avoiding frequent redesigns

- Faster time-to-market with flexible task allocation

- Improved throughput by adding capacity incrementally

- Stronger long-term ROI through adaptability

How Boston Engineering Drives Manufacturing Scalability

Boston Engineering brings scalability to manufacturing automation through:

- Custom architecture and integration strategies built to handle growth and change.

- Roadmaps for future capability growth so you can adopt new technologies without disruption.

- Ongoing system evaluation and tuning as manufacturing needs evolve.

Whether you’re upgrading existing automation or building new systems, Boston Engineering helps you engineer solutions that grow with demand.

.png?width=760&height=317&name=Robotics%20Background%20image%20(2).png)

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!