Future-Proof Your Warehouse: How Scalable Robotics Unlocks Growth and Resilience

In a world where supply chains face constant change—from seasonal demand swings to labor shortages—warehouses must adapt or lose ground.

Robotics and automation have already proven they can boost throughput and accuracy. But the real game changer isn’t just automation—it’s scalable automation.

Scalable robotic systems are designed to grow with your business, accommodate new workflows, and adopt emerging technologies without expensive redesigns. This blog explores what scalability means for warehouse automation, why it matters, and how Boston Engineering builds future-proof solutions that help warehouses stay agile and resilient.

Continue reading below to learn more

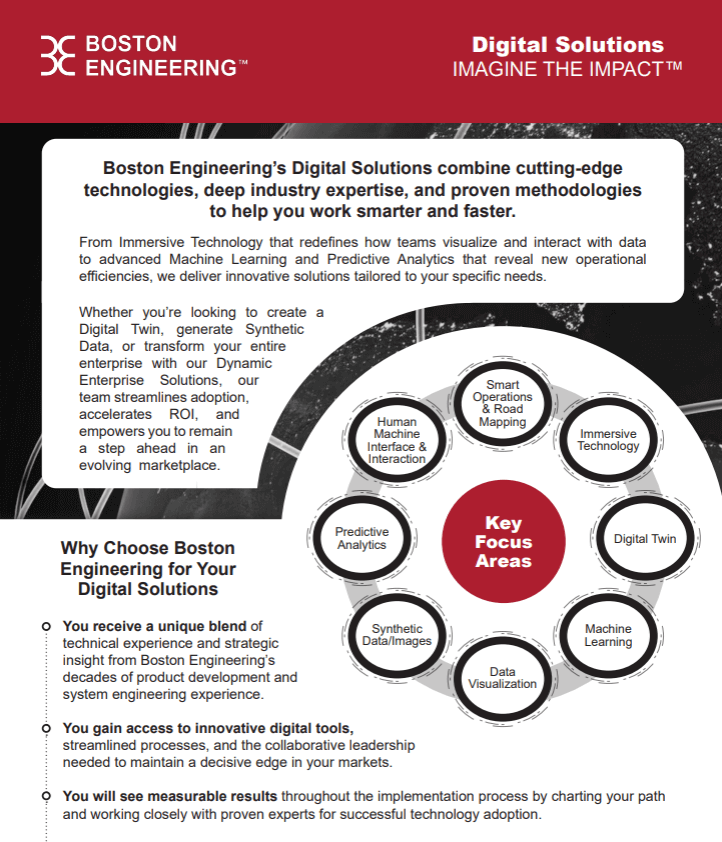

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

What Does Scalability Mean in Warehouse Robotics?

Scalability refers to a robotic system’s ability to expand, adapt, and evolve over time based on operational needs. Rather than building a system that only fits today’s demand, scalable systems prepare warehouses for tomorrow’s challenges.

A scalable warehouse robotics solution can:

- Add more robots easily as workload increases

- Integrate new sensing or software capabilities

- Re-task robots for new warehouse functions

- Absorb layout changes without costly retrofits

This is critical in environments where order volumes, peak seasons, and SKU diversity continually fluctuate.

Why Scalability Matters for Warehouse Operations

Warehouses increasingly operate in fast-moving and unpredictable markets. Scalability delivers strategic advantages:

1. Adaptability to Business Growth

As warehouse demand increases, you shouldn’t need to redesign your automation infrastructure. Scalable systems allow you to seamlessly add capacity—whether that’s expanding fleets of Autonomous Mobile Robots (AMRs) or enabling additional tasks without system rewrites.

2. Reduced Total Cost of Ownership

Traditional automation often forces forklift-like upgrades when requirements change. Scalable systems minimize expensive overhauls by using modular, extensible architectures that grow with you.

3. Rapid Response to Market Shifts

Whether you’re facing holiday surges or a new product launch, scalable systems enable quick, incremental expansion to meet demand without disruption.

Key Components of Scalable Warehouse Robotics

To build scalable systems, you need the right engineering foundation:

• Modular Hardware & Firmware

Robots and modules designed to accept upgrades, and new payloads make it easy to extend capabilities as operational needs change.

Example: Upgrading a robot’s sensor suite to improve navigation in cluttered zones without replacing the whole base.

• Flexible Software Frameworks

Using scalable platforms such as ROS and ROS2 enables robots to accept new algorithms, support fleet management, and integrate AI services over time.

• Unified Control and Communication

Robotic fleets need consistent communication frameworks and control hierarchies so that adding units doesn’t introduce conflicts or bottlenecks.

Real-World Warehouse Scalability: AMRs in Action

Consider a distribution center experiencing rapid e-commerce growth. Rather than being limited by the number of robots originally deployed, a scalable AMR fleet can expand organically as cargo throughput increases, keeping order fulfillment times low even during peak periods.

Scalability also allows warehouses to reassign tasks—like transitioning robots from material handling to cross-docking or replenishment—without costly reengineering.

Boston Engineering’s Approach to Warehouse Scalability

Boston Engineering specializes in robotic systems that are built to evolve with your business:

- Robust architectural design that supports scaling fleets, upgrading sensors, and integrating future technologies without disruption.

- Tailored system integration based on your workflows and operational constraints.

- Ongoing support and optimization to maintain performance as your needs change.

By designing automation that scales, warehouses can maintain competitive performance and reduce long-term costs.

.png?width=760&height=317&name=Robotics%20Background%20image%20(2).png)

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!