From Idea to Market: Boston Engineering’s Proven Approach to Complete Medical Product Development

Medical Device Product Development Needs More Than Engineering

Medical device executives know the stakes: innovative ideas are only valuable if they can become finished products — safely, efficiently, and at scale. While many engineering firms offer technical solutions, few combine technical depth with project management discipline, regulatory awareness, and full lifecycle expertise.

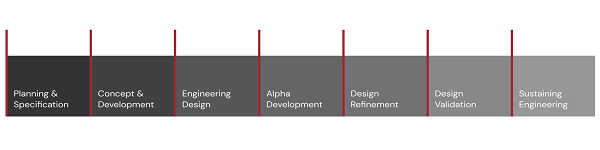

That’s where Boston Engineering stands apart. We don’t just engineer solutions — we engineer products. From the earliest idea through development, verification, regulatory review, and scaling to production, we guide innovators through the most efficient path to market.

-1.png?width=760&height=95&name=Untitled%20design%20(7)-1.png) The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

(continued from above)

![]()

The Common Thread in Our Work

Across dozens of successful projects, we’ve delivered:

- Integration of complex technologies — robotics, embedded systems, control systems, and digital solutions.

- Design for success — manufacturability, reliability, usability, and cost built in from the start.

- Regulatory readiness — complete, traceable documentation that accelerates approval.

- Project leadership — experienced program managers guiding multi-disciplinary teams.

- Reduced risk, faster outcomes — avoiding late-stage surprises that delay market entry.

The results? Wearables that monitor patients securely, consumables produced at scale, ventilators that meet critical needs, and surgical tools that improve precision and usability.

Introducing the Blog Series

Introducing the Blog Series

This blog is the first in a 12-part series highlighting real-world examples of Boston Engineering’s end-to-end medical device product development capabilities. Each article focuses on a theme critical to medical executives and illustrates it with three project case studies.

Here’s what’s ahead in the series:

- End-to-End Development Leadership

- Robotics in MedTech

- Designing Smarter Devices with Embedded Intelligence

- Accelerating Time-to-Market Through Digital Solutions

- Design for X: From Prototype to Scalable Production

- Control Systems for Life-Critical Devices

- Diagnostics Reimagined

- Connected Care & IoT Devices

- Improving Clinician Adoption with Human-Centered Design

- Rapid Innovation Under Pressure

- Reliability by Design

- The Future of MedTech

Why Product Development Expertise Matters

For medical device executives, the challenge isn’t just developing breakthrough technology — it’s bringing it to market efficiently, safely, and at scale. Many engineering partners can solve isolated technical challenges, but few understand the entire product development lifecycle.

At Boston Engineering, we do both. We combine deep technical expertise with structured project management and a proven track record of guiding devices from idea to finished product. The following examples highlight how our team’s experience and process accelerate innovation while reducing risk.

AL & ML in Health Care - The Medical Workplace Multiplier

In this new Whitepaper, learn how AI and ML can enhance the medical workforce’s abilities and improve patient outcomes.

In this new Whitepaper, learn how AI and ML can enhance the medical workforce’s abilities and improve patient outcomes.

While some view AI as a potential job replacement threat, the reality is that these advanced capabilities are better positioned as “workforce multipliers” that will amplify the abilities of doctors, nurses, technicians and other medical professionals.

Download your Free Copy Today!

Artificial intelligence and machine learning are emerging technologies that have immense potential to reshape healthcare delivery and medical practice.

Case Example 1: Developing a Wearable Patient Monitoring Device

One innovator needed a wearable monitoring system to continuously track patient health data. The challenge wasn’t just creating the electronics — it was designing a complete product that was lightweight, low-power, secure, and manufacturable.

Boston Engineering:

- Developed custom electronics and firmware optimized for continuous operation.

- Designed secure wireless communication for HIPAA-compliant data transmission.

- Ensured the design met ergonomic requirements for long-term patient use.

- Applied Design for Manufacturability (DfM) principles to prepare for large-scale production.

Outcome: The result was a smart, connected wearable that provided clinicians with real-time insights while maintaining patient comfort and extending device lifespan.

Case Example 2: Scaling a Diagnostic Consumable for Mass Production

Case Example 2: Scaling a Diagnostic Consumable for Mass Production

A client had a working diagnostic consumable prototype, but the design was too costly and complex for manufacturing at commercial scale. Without redesign, the product risked commercial failure.

A client had a working diagnostic consumable prototype, but the design was too costly and complex for manufacturing at commercial scale. Without redesign, the product risked commercial failure.

Boston Engineering:

- Simplified the assembly process, reducing complexity and improving reliability.

- Selected materials optimized for biocompatibility, performance, and cost.

- Conducted usability testing with clinicians to ensure ease of handling.

- Integrated manufacturing considerations early in the redesign process.

Outcome: Manufacturing costs were significantly reduced while reliability improved, enabling the consumable to scale from prototype to mass production successfully.

Case Example 3: Advancing a Next-Generation Ventilator Platform

During a surge in demand for critical care devices, an innovator needed a ventilator platform that was reliable, safe, and capable of rapid production. The control systems and redundancy requirements were especially demanding.

Boston Engineering:

- Designed closed-loop control systems with redundant safety features.

- Integrated real-time sensing and embedded software for precise operation.

- Partnered with our Digital Solutions COE to simulate performance under diverse clinical conditions.

- Structured documentation to streamline regulatory review.

Outcome: The ventilator platform achieved improved reliability and safety, while its design scalability allowed rapid manufacturing scale-up during urgent demand.

The Common Thread: Project Management and Process

The Common Thread: Project Management and Process

Across these three programs — a wearable, a diagnostic consumable, and a ventilator — the common factor was not just technical expertise, but end-to-end product development leadership.

Boston Engineering’s project managers bring:

- Systems thinking: Ensuring every subsystem integrates into the larger device goals.

- Process discipline: Aligning with FDA, ISO, and IEC standards from the outset.

- DfX foresight: Designing for manufacturability, usability, and scalability from day one.

- Risk management: Identifying and mitigating challenges early, before they impact timelines.

A Partner for Complete Medical Product Development

For executives leading medical device innovation, success depends on more than solving technical problems. It requires a partner who understands the full product lifecycle — and can help you move from concept to clinic efficiently, effectively, and with confidence.

At Boston Engineering, we’ve guided wearables, consumables, critical care devices, and more through the complete journey. Our proven combination of technical expertise, structured project management, and regulatory awareness means you can trust us to deliver.

If you’re developing your next breakthrough device, partner with Boston Engineering to get it from idea to finished product — faster, safer, and smarter.

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach in medical device design & development

Applying Design for X (DFX) methodologies upfront in medical device development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for your medical engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next medical device DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!