Smart Engineering Keeps Semiconductor Production Moving

In industries driven by precision and innovation, product obsolescence doesn’t have to mean product failure.

In high-tech industries like semiconductor manufacturing and life sciences, even a single obsolete component can jeopardize entire product lines. One industrial brand, with products essential to these cutting-edge environments, faced a critical challenge: obsolete parts were threatening performance, delaying production, and risking lost revenue.

To avoid costly redesigns and protect product integrity, the company turned to Boston Engineering—a trusted partner in solving complex engineering problems—for a strategic solution.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

(continued from above)

The Challenge: Obsolescence Without Compromise

With technology evolving rapidly, component obsolescence is inevitable. But for this manufacturer, the stakes were high:

-

Their products served semiconductor fabrication and life sciences research, where performance and reliability are non-negotiable.

-

Replacing outdated parts without altering form, fit, or function was essential to avoid triggering full-scale product redesigns.

-

There was also a need to streamline part counts, improving efficiency and reducing manufacturing complexity.

This wasn’t just a technical fix—it was a mission to future-proof critical systems without disrupting existing production workflows.

Boston Engineering’s Approach: Engineering with Precision and Foresight

Boston Engineering tackled the problem with a strategic and practical mindset, focusing on long-term sustainability and seamless integration. Their approach included:

- Component Replacement with Identical Form, Fit, and Function – Every substitute component was engineered to drop into place without altering the product’s design, behavior, or performance.

- Avoiding Invasive Redesigns – By focusing on backwards-compatible solutions, Boston Engineering eliminated the need for costly and time-consuming reengineering.

- Reducing Part Count Where Possible – Streamlining components helped simplify the supply chain, enhance reliability, and lower manufacturing costs.

Interested in providing your product development team with DFX skills? Learn More about our Applied DFX process and development workshops.

(continued from above)

The Impact: Sustained Performance and Cost Savings

Boston Engineering has provided ongoing support across multiple product lines, helping the client navigate the ever-changing landscape of component availability. The impact has been substantial:

Reliable Engineering Substitutions – Products remained operational and high-performing; even as individual parts aged out of availability.

Lower Costs – By reducing overall component complexity, the client realized significant savings in both parts and manufacturing.

Uninterrupted Production – Prevented costly production delays and lost sales, ensuring that vital systems stayed in market and on schedule.

Preserved Performance Benchmarks – The integrity and quality of the end product remained uncompromised across all updates.

Building Resilience into Semiconductor Systems

Boston Engineering’s smart, systems-level approach ensures companies can evolve with technology—without losing time, money, or performance. Whether it's retrofitting legacy systems or planning for long-term sustainability, Boston Engineering helps manufacturers maintain momentum in semiconductor production and beyond.

Facing obsolescence in your critical systems?

Contact Boston Engineering today to explore how we can help you stay ahead of component challenges—without compromising your product or your progress.

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

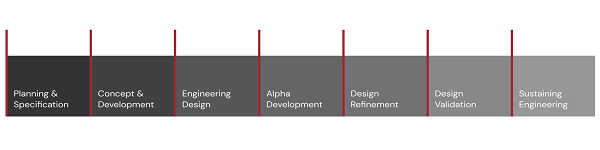

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!