Enhancing Semiconductor Testing: A Modular Approach to Multi-Product Test Stands

The semiconductor industry thrives on precision, efficiency, and adaptability.

When an OEM needed an automated test solution for its extensive line of motor amplifiers and digital controllers, it required a scalable, flexible, and high-performance testing system. Boston Engineering delivered a cutting-edge multi-product test stand, transforming the client’s testing process and increasing efficiency across their operations.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

(continued from above)

The Challenge: Automating Testing for Multiple Products

The client faced a common challenge in semiconductor manufacturing—the need to automate and streamline testing for a diverse product lineup. The existing processes were time-consuming, rigid, and difficult to scale. The client needed a custom test stand that could:

- Handle a wide range of motor amplifiers and digital controllers.

- Easily update and adapt to new test sequences without extensive rework.

- Provide a unified testing interface for all products, simplifying operations.

Given the high complexity and precision requirements of semiconductor component testing, Boston Engineering developed a modular and scalable solution tailored to the client's needs.

Boston Engineering’s Approach: A Custom, Scalable Test Stand

Boston Engineering designed and built a custom multi-product test stand with a focus on modularity, automation, and ease of use.

Key engineering solutions included:

- Modular Design for Quick Updates – The system was designed to allow fast modifications and seamless expansion to accommodate new products or testing requirements.

- Flexible Test Sequence Management – Engineers could add or modify test sequences without recompiling code, significantly reducing downtime and enhancing adaptability.

- Unified Interface – A single software interface was developed to streamline testing across multiple products, reducing complexity for engineers and operators.

- Advanced Engineering Features:

- LabVIEW software running on Windows, ensuring a user-friendly and highly adaptable testing environment.

- 19” rack-mount chassis, providing an efficient and space-saving hardware setup.

- High- and low-voltage signal conditioning trays, ensuring accurate testing across a broad range of power levels.

Interested in providing your product development team with DFX skills? Learn More about our Applied DFX process and development workshops.

(continued from above)

The Impact: Increased Efficiency & Testing Flexibility

By implementing this advanced test stand, Boston Engineering helped the client streamline their testing process, reduce manual intervention, and improve overall efficiency. The results included:

Faster testing cycles – Automated, optimized processes reduced testing time, improving production throughput.

Increased adaptability – The modular system enabled quick updates, allowing seamless integration of new products and test protocols.

Improved accuracy – High- and low-voltage signal conditioning ensured precise, reliable measurements for semiconductor components.

Enhanced usability – A single, intuitive interface simplified operations, reducing the learning curve for engineers.

A Smarter Approach to Semiconductor Testing

With its expertise in automated testing solutions, modular system design, and precision engineering, Boston Engineering delivered a custom multi-product test stand that transformed the client’s semiconductor testing process. The result? Greater efficiency, improved accuracy, and a scalable system that supports future innovation.

Looking to optimize your engineering systems?

Contact Boston Engineering today to explore how we can enhance your testing efficiency and product reliability.

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach

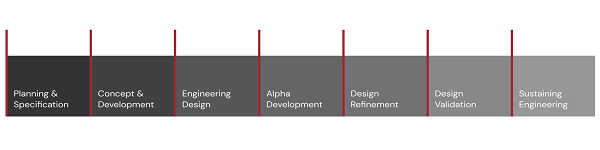

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!