Unlocking Strategic Value: What Executives Should Expect from Smart Operations

Smart Operations have become more than a buzzword—they are the engine driving modern manufacturing and product development.

For executives and decision-makers, the question is no longer if to adopt smart operations, but what strategic outcomes can be expected and how quickly can they be realized.

While most leaders understand the promise of Predictive & Proactive Maintenance, Interconnectivity, IoT Integration, and Data-Driven Decision-Making, there is a broader and often untapped spectrum of benefits that Smart Operations deliver.

Here are the high-value outcomes manufacturing and product development leaders should expect from a well-executed smart operations strategy:

Continue reading below to learn more

The Boston Engineering Digital Solutions Portfolio

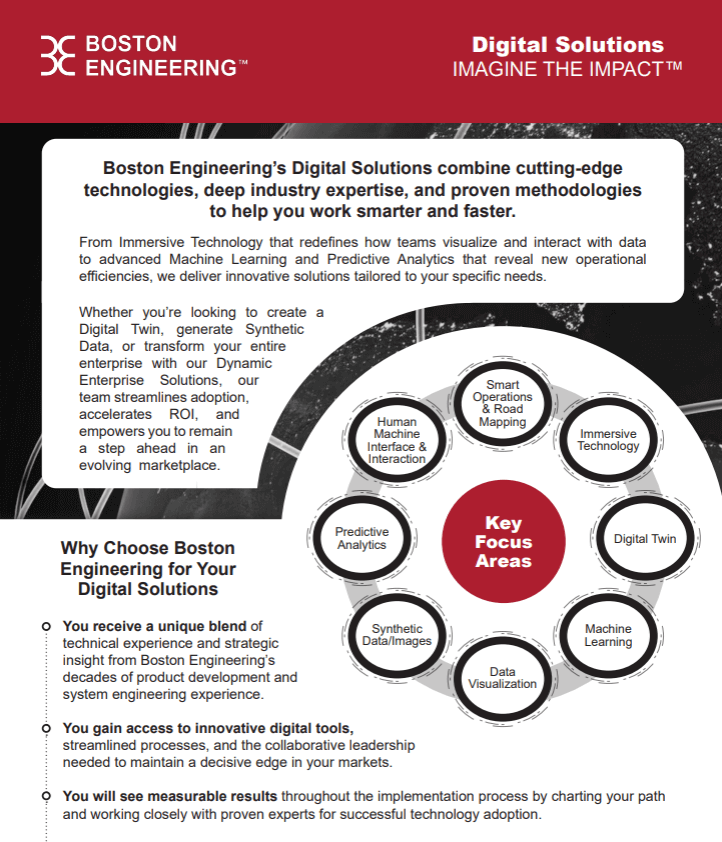

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

1. Energy Efficiency and Sustainability

Strategic Impact: Reduce operating costs while meeting sustainability targets.

Smart operations integrate real-time monitoring with intelligent control systems to reduce waste, optimize energy use, and support ESG commitments. The result is improved margins and stronger environmental performance—a win for the bottom line and brand reputation.

Example: A global beverage producer adjusts chillers, lighting, and HVAC systems based on ambient conditions and production scheduling, resulting in a 15% reduction in energy costs.

2. Supply Chain Resilience and Visibility

Strategic Impact: Anticipate disruptions and respond with agility.

Strategic Impact: Anticipate disruptions and respond with agility.

Connected systems and analytics offer end-to-end visibility across the supply chain. Companies can monitor inventory levels, supplier statuses, and logistics flows in real time to proactively manage risks.

Example: A consumer electronics firm detects delays from an overseas supplier and reroutes orders to a secondary vendor, avoiding line stoppages and maintaining delivery commitments.

3. Real-Time Quality Assurance

Strategic Impact: Improve first-pass yield and customer satisfaction.

Integrated sensors, machine vision, and AI enable quality monitoring as products are made—not just after. This proactive approach detects problems earlier, reduces scrap, and increases throughput.

Example: An automotive parts manufacturer leverages AI-powered cameras to detect microscopic defects during assembly, improving first-pass quality by 25% and reducing warranty claims.

4. Workforce Augmentation and Safety

Strategic Impact: Empower teams while reducing operational risk.

Smart operations augment the human workforce with robotics, augmented reality (AR), and digital instructions. This reduces the cognitive and physical load on workers and enhances safety in high-risk environments.

Example: Maintenance technicians use AR glasses to receive real-time repair guidance, reducing training time and eliminating 60% of common service errors.

5. Continuous Process Optimization

Strategic Impact: Unlock compounding gains in productivity and efficiency.

Machine learning and control systems automatically fine-tune operations based on data feedback loops. Over time, these systems reveal process improvements that might otherwise go unnoticed.

Example: A specialty chemicals plant uses AI to continuously adjust mixing parameters, boosting yield by 3% and reducing energy input per unit.

6. Enhanced Customer Responsiveness and Customization

Strategic Impact: Accelerate delivery timelines and adapt to market shifts.

Smart factories are built for agility. Connected systems allow for fast changeovers, order-driven scheduling, and personalized production at scale.

Example: A contract manufacturer quickly switches between product variants with minimal downtime thanks to smart tooling and automated scheduling.

7. Asset and Lifecycle Optimization

Strategic Impact: Maximize return on capital investments.

Smart Operations use simulations, digital twins, and predictive analytics to extend asset life and minimize performance degradation.

Example: A wind energy operator uses digital twins to model turbine performance under different conditions, enabling them to optimize servicing and extend asset lifespan by 20%.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Making the Business Case

These outcomes aren’t theoretical—they are real, measurable, and already being realized by forward-thinking organizations. Each outcome builds on the others, creating a flywheel of operational improvement that enhances competitiveness, customer satisfaction, and profitability.

As a decision-maker, investing in Smart Operations is not just about digitization. It’s about transforming the way your organization thinks, operates, and delivers value.

Contact us to talk about similar opportunities in your operations

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Partnering for Smart Success

At Boston Engineering, we specialize in helping manufacturers and product innovators unlock the full potential of smart operations. Our integrated approach combines technology, strategy, and execution to accelerate your journey toward operational excellence.

Let’s talk about how you can go beyond the basics and capture the full range of strategic benefits from your smart operations investment.

Partner with Boston Engineering to develop your roadmap for connectivity and data-driven decision-making. Our multidisciplinary expertise ensures seamless integration across technologies and systems, delivering transformative results for your operations.

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!