The Strategic Role of Design for Reliability in Product Development

Design for Reliability (DFR) is not merely a technical consideration; it is a strategic imperative that shapes the entire product development strategy.

The Strategic Essence of Design for Reliability:

Reliability is not just a desirable feature; It's a strategy to secure a strong, long term market position. Successful companies repeatedly design beyond mere functionality, aiming to create products that consistently perform at the highest level over their lifespan. Commitment to DFR highlights the importance in proactively identifying failure modes, improving product lifecycle management, enhancing quality assurance, minimizing downtime and maintenance costs, and ultimately, building market differentiation and brand trust.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

-1.png?width=762&height=105&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

DFR can be a cornerstone for a successful product performance and sustained market advantage.

For companies aspiring to not just meet but exceed customer expectations, incorporating DFR into their product strategy paves the way for sustained success in the competitive marketplace. Here's how:

- Proactive Identification of Failure Modes: DFR encourages a proactive approach to reliability by identifying potential failure modes early in the design phase. This foresight allows companies to address reliability concerns before they become critical issues, ensuring a product that meets or exceeds performance expectations.

- Improved Product Lifecycle Management: Design for Reliability takes into account the entire product lifecycle. By considering factors such as material durability, wear and tear, and environmental conditions, companies can design products that stand the test of time. This longevity contributes to customer satisfaction and builds a positive brand reputation.

- Enhanced Quality Assurance: Quality is a cornerstone of reliability, and DFR contributes significantly to quality assurance. By designing products with reliability in mind, companies can implement rigorous testing processes, reducing the likelihood of defects and ensuring that each product meets stringent quality standards.

- Minimized Downtime and Maintenance Costs: Reliable products translate to minimized downtime and reduced maintenance costs for end-users. DFR anticipates potential failure points and designs products to be robust and durable, resulting in fewer disruptions for customers and lower long-term ownership costs.

- Market Differentiation and Brand Trust: In a market saturated with choices, reliability becomes a key differentiator. Products that consistently perform well build trust among customers, leading to brand loyalty and positive word-of-mouth marketing. DFR, therefore, becomes a strategic tool for companies seeking to differentiate themselves in the market.

Understanding the Importance of a DFX approach

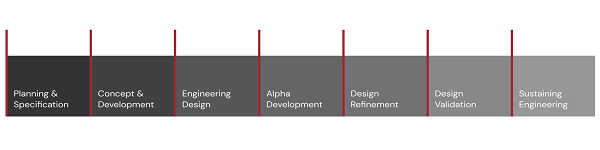

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!