Solving Factory Automation Pain Points with Reliable Robotics Engineering

Factory automation promises higher productivity, lower costs, and improved quality.

Yet many automation initiatives struggle—not because of ambition, but because reliability and safety weren’t engineered from the beginning.

This blog examines the most common factory automation pain points and explains how robust robotics engineering transforms automation from a risk into a long-term competitive advantage.

Continue reading below to learn more

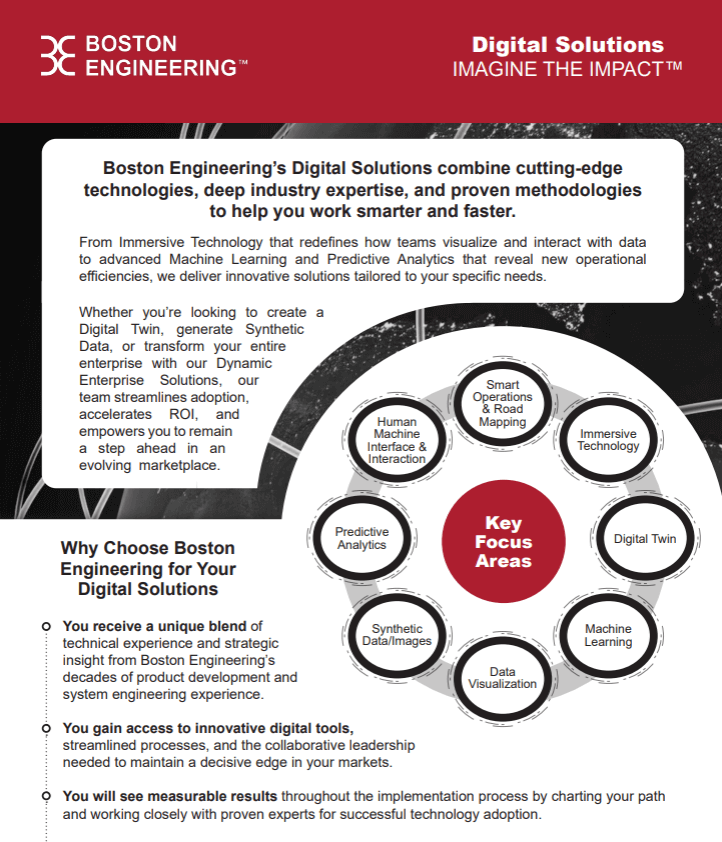

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

The Most Common Factory Automation Challenges

Even experienced manufacturers face recurring obstacles:

- Unplanned downtime caused by fragile automation systems

- Safety risks in mixed human-robot environments

- Difficulty integrating robotics with legacy equipment

- Automation that performs well in demos—but fails under real production stress

These issues often stem from focusing on speed and functionality before safety and reliability.

Engineering Principles That Enable Reliable Factory Automation

1. Reliability Engineering from Day One

How it works:

Reliability engineering evaluates failure modes, component lifecycles, and operational stresses during the design phase.

Why it matters:

Anticipating failure prevents production disruptions and costly redesigns later.

2. Safety-Centered Human-Robot Interaction

Modern factories increasingly rely on collaborative robotics.

How it works:

Robots are designed with force limiting, safe stopping, intelligent sensing, and clear human-machine interfaces.

Why it matters:

Safe interaction improves worker acceptance and enables true collaboration rather than separation.

3. Robust System Integration

Automation rarely exists in isolation.

How it works:

Robotics systems are integrated with PLCs, MES platforms, quality systems, and legacy machinery.

Why it matters:

Seamless integration prevents data silos and ensures automation enhances—not disrupts—existing workflows.

4. Validation Through Testing and Simulation

How it works:

Digital simulations and real-world testing replicate production stresses before full deployment.

Why it matters:

Testing uncovers weaknesses early, reducing commissioning delays and operational risk.

The Business Impact of Reliable Factory Automation

When reliability and safety are engineered together, manufacturers gain:

- Higher equipment availability

- Predictable production schedules

- Improved product quality

- Safer working environments

- Faster ROI from automation investments

How Boston Engineering Helps Manufacturers Succeed

Boston Engineering partners with manufacturers to design, validate, and deploy automation systems built for real-world factory conditions—not just lab environments.

Our multidisciplinary expertise ensures:

- Automation that withstands continuous operation

- Systems that evolve with production demands

- Compliance with safety standards without sacrificing performance

.png?width=760&height=317&name=Robotics%20Background%20image%20(2).png)

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!