Remote Monitoring as Competitive Strategy

Do you know who in your industry is using remote monitoring? If you said yes, then you have probably begun thinking about the ways to incorporate this level of post market connectivity to your products.

If you answered no, then chances are you're falling behind your competition and need to begin considering what remote monitoring, as an integral part of your competitive strategy, can mean for future revenue growth.

Below are several areas you should consider when analyzing the impact that the digital thread, and remote monitoring, can have on your bottom line.

Eliminate Performance Blind Spots

Failure to truly understand how customers are using your products represents a missed opportunity to make user-driven enhancements and to identify untapped market needs. To address this challenge, consider incorporating secure capabilities to gain live product performance monitoring and to apply analytics to improve business operations.

Traditional in field feedback programs only capture snapshots of past product performance. This includes customer surveys, focus groups, anecdotes from sales teams, and field action documentation. Imagine the impact of seeing what your products are doing in the field, in real time!

Drive Business Value through Monitoring

To gain timely insights into field use, forward thinking firms are incorporating sensors into their product designs to monitor safety, performance, and usage trends. Key performance indicators (KPIs) can include motor RPMs, device vibration, temperature, and battery power levels.

- Monitor an aggregated dashboard of all devices

- Display alerts for performance that is out of range

- Analyze and display device trends, averages, etc. (e.g., if procedure times are 30% longer than projected, it could cause a device to run at the high-end of its accepted temperature range)

- Detect malfunctions before they escalate into safety issues or reportable events

- Drill down to individual device performance (e.g., review the RPM motor history of a single device)

- Gather data required for adverse event reporting quickly

To comply with quality processes, remote monitoring findings can be integrated into a company’s overall risk management system, including design failure mode and effect analysis (DFMEA) processes. Field complaints and other information uncovered via in field feedback are important inputs for management review. Capturing all root-cause failure investigation findings, for example, will provide clear steps for corrective actions.

Frame New Product Development Accurately

Despite the rigor applied to DFMEAs and risk management during new product development, this process is far from complete and does not address unintended team biases or other limitations including:

- Assumptions: Are you testing the right parameters or use cases?

- Cybersecurity: Safeguarding a connected device requires data protection to be central throughout the product development process – from early concepts; software and hardware selection; prototyping; validation of business processes for the data; through ongoing device management for performance and security.

- Usability testing: Is there too much weight placed on select medical advisors or key opinion leaders instead of broad user representation?

- Sample size: Is there access to field data across multiple geographies/environmental conditions? And is the sample size large enough to conduct meaningful analysis?

.png?width=1200&name=Fish%20Banner_Robotics%20(1).png)

For new product line/platform development, remote monitoring can be piloted with prototypes for deeper insights, and for uncovering solutions to the above concerns.

No amount of lab testing can replicate real-world environments for globally distributed products. Device temperature may trend high in parts of Asia due to electrical current fluctuations, while regions in North America may face network connectivity interruptions.

Prototype performance monitoring will also provide the team with an opportunity to investigate significant usage variations among geographies. As an example, does one group surgical process, or is there a usability challenge

due to device size and weight?

Launch Enhancements Rapidly with User Feedback

Once commercialized, remote monitoring data can play a pivotal role in shaping the product development roadmap (multi-generational platform development). Tracking usage and performance provides companies with unfettered information. Product device teams can focus on concrete actions instead of debating opinions. Regular feedback from the field will enable the product management team to re-prioritize enhancements and to accelerate subsequent releases.

This information can provide product development teams with important information to guide new product development. Examples:

- How do customers typically use the device (e.g., settings most and least used, etc.)?

- Are component designs meeting requirements?

- Are components over designed?

- Have usage patterns changed since the product introduction?

The Interconnectivity Impact

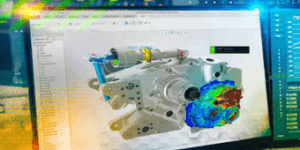

The digital thread is leading to new process innovations that enhance operations and increase profitability for organizations across all industries. Advanced technologies such as IoT, AR, and RM are key ingredients of realizing the potential impact. Capturing the benefits of a digital transformation starts with understanding your business case—and how smart connected products, with the analytics and operational efficiencies they enable, can add value to all areas of your enterprise ready to make the investment.

Ready to Make the Change? Across industries, businesses are facing up to the risks—including workforce management challenges, the impact of not updating existing infrastructure and legacy technology, and security risks—and making the investment. Boston Engineering has the team and the experience to make your implementation of the digital thread a success. If you are considering making the transition to a digital first organization, we would appreciate the opportunity to lead you through the many challenges involved in making it a reality. Reach out to us today and let’s start the conversation.

Ready to Make the Change? Across industries, businesses are facing up to the risks—including workforce management challenges, the impact of not updating existing infrastructure and legacy technology, and security risks—and making the investment. Boston Engineering has the team and the experience to make your implementation of the digital thread a success. If you are considering making the transition to a digital first organization, we would appreciate the opportunity to lead you through the many challenges involved in making it a reality. Reach out to us today and let’s start the conversation.

Contact

For additional information about technical specifications and availability, please contact us at info@www.boston-engineering.com.

.png)