Is your product future ready?

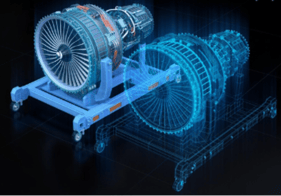

Companies often struggle to get their product to manufacturing due to numerous reasons. To leverage world-class advanced manufacturing methodologies, tools, and expertise, your product design must fit this depiction. How can you ensure a seamless transition from design to manufacturing? How can you design your product to stand the challenges of the future?

When designing your product, there are specific pieces to keep in mind for the future. Embedded systems and digital solutions can help your organization reduce future costs, future-proof your product, and design for optimized manufacturing. Digital solutions provide design, storage, and management opportunities to not only reduce costs and design efficiently but also make the handoff to manufacturing and the manufacturing process itself seamless and therefore less costly.

Challenges halting product development growth:

- Component Obsolescence: Component obsolescence is a major issue for companies that design and manufacture equipment. As technical developments are taking place at a

.png?width=206&height=96&name=Component%20obsolescence%20(1).png) rapid rate, components come and go very quickly. One obsolete component can cause major financial losses for a company as a product can easily become inoperative. When designing your product, the embedded systems must be created with the future in mind - build these systems for future components, future software, etc.

rapid rate, components come and go very quickly. One obsolete component can cause major financial losses for a company as a product can easily become inoperative. When designing your product, the embedded systems must be created with the future in mind - build these systems for future components, future software, etc. - Modern Manufacturing Requirements: Manufacturing.gov defines advanced manufacturing as “the use of innovative technologies to create existing products and the creation of new products, including production activities that depend on information,

automation, computation, software, sensing, and networking”. Advanced manufacturing is very customized, technical, skilled, and requires digital infrastructure. Although advanced manufacturing is transforming industries, it is requiring modern advancements from product companies. Digital solutions are assisting organizations to modernize their designs and processes for an easy transition to manufacturing. The design, storage, and management of all of your designs and tech must be built as a digital system to operate with today's manufacturers

automation, computation, software, sensing, and networking”. Advanced manufacturing is very customized, technical, skilled, and requires digital infrastructure. Although advanced manufacturing is transforming industries, it is requiring modern advancements from product companies. Digital solutions are assisting organizations to modernize their designs and processes for an easy transition to manufacturing. The design, storage, and management of all of your designs and tech must be built as a digital system to operate with today's manufacturers - Lifecycle Obstructions: What does time bring? New technology. Especially in this day in age, the turnover of new technology is constant and rapid. This makes it almost impossible for companies to maintain a long-term product lifecycle. If not planned correctly, engineering updates must be regularly made in order to continuously extend the lifecycle. This can become very costly, and oftentimes not even worthwhile as it becomes a neverending cycle. Similar to the solution for obsolete components, your embedded systems design can help plan for an extended product lifecycle. Digital solutions also provide opportunities for planning, design, testing, and storage that help plan for future tech and iterations, as well as reduce costly development iterations.

For almost three decades, Boston Engineering has designed, developed, and optimized devices and technologies that the industrial and commercial industry relies on to improve lives, enrich quality, and reduce costs. We provide solutions to the challenges of future-proofing your products for manufacturing.

Our expertise includes industrial design and product redesign, sensors and control systems, robotics technical innovation, and digital software solutions.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a monthly summary of our most impactful posts!

.png)