Understanding the Power of Digital Twins: Revolutionizing Product Development

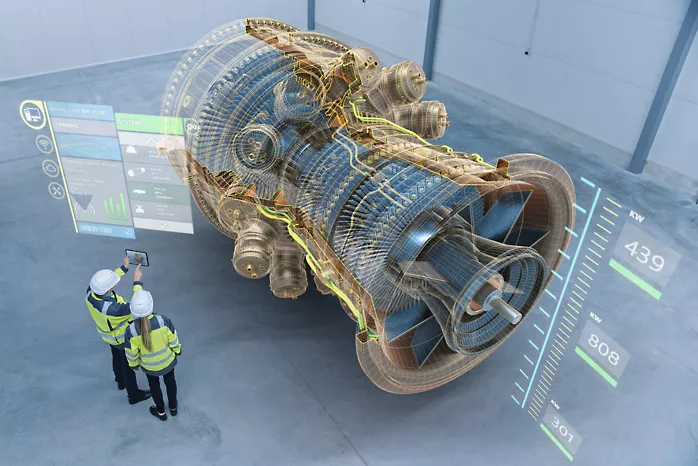

In recent years, the digital landscape has witnessed a transformative phenomenon in product development through the advent of digital twins. The concept of a digital twin, a virtual replica of a physical product or system, has revolutionized the way companies design, create, and maintain their offerings. This innovative technology has redefined product development, enhancing efficiency, reducing costs, and ultimately revolutionizing the entire process.

The Birth of Digital Twins

Digital twins represent a virtual doppelgänger of a physical product, mirroring its characteristics and behavior in the digital realm. This simulation technology integrates data from various sources such as sensors, IoT devices, and historical records to create a real-time representation of the physical counterpart. This digital clone evolves and learns, reflecting changes in its physical twin, allowing for predictive analysis and optimization.

product, mirroring its characteristics and behavior in the digital realm. This simulation technology integrates data from various sources such as sensors, IoT devices, and historical records to create a real-time representation of the physical counterpart. This digital clone evolves and learns, reflecting changes in its physical twin, allowing for predictive analysis and optimization.

The Role in Product Development

The application of digital twins in product development is multifaceted. It enables designers and engineers to conduct simulations, test different scenarios, and evaluate performance virtually before physical prototypes are produced. This not only expedites the design process but also mitigates risks and reduces costs associated with physical trial and error.

Enhancing Efficiency and Innovation

One of the key advantages of digital twins is their ability to streamline the innovation cycle. Companies can test new concepts and ideas rapidly, modifying and improving the digital model before moving to the physical production phase. This capability significantly accelerates innovation and time-to-market for new products.

One of the key advantages of digital twins is their ability to streamline the innovation cycle. Companies can test new concepts and ideas rapidly, modifying and improving the digital model before moving to the physical production phase. This capability significantly accelerates innovation and time-to-market for new products.

Predictive Maintenance and Performance Optimization

Another area where digital twins excel is in predictive maintenance and performance optimization. By continuously collecting and analyzing real-time data from the physical product, digital twins can anticipate maintenance needs, identify potential issues, and recommend improvements. This proactive approach minimizes downtime, maximizes performance, and prolongs the product's lifecycle.

Revolutionizing Product Development with Boston Engineering

Boston Engineering stands at the forefront of digital twin technology. Our expertise in developing and implementing these digital replicas has assisted numerous companies in revolutionizing their product development strategies. By leveraging advanced simulation tools and their deep understanding of various industries, Boston Engineering has empowered companies to innovate and grow with confidence.

technology. Our expertise in developing and implementing these digital replicas has assisted numerous companies in revolutionizing their product development strategies. By leveraging advanced simulation tools and their deep understanding of various industries, Boston Engineering has empowered companies to innovate and grow with confidence.

Looking Ahead: Future Implications

As technology continues to evolve, the potential for digital twins expands. The integration of artificial intelligence, machine learning, and further advancements in IoT will only bolster the capabilities of these digital replicas. The future holds the promise of even more precise and comprehensive digital twins, further revolutionizing product development across industries.

Digital twins have emerged as a game-changer in the realm of product development, empowering companies to innovate, enhance efficiency, and optimize performance. Their ability to simulate, predict, and optimize is reshaping the way products are conceived, designed, and maintained. Boston Engineering's proficiency in harnessing the power of digital twins positions us as a leading force in driving innovation and growth for companies seeking to revolutionize their product development processes. Embracing this technology promises not just evolution, but a revolution in the way we create and maintain our physical world.

For almost three decades, Boston Engineering has designed, developed, and optimized devices and technologies the medical community relies on to save lives, enrich quality of life, and reduce costs to the healthcare system. We provide solutions to the challenges in the adoption of surgical robotics.

Our expertise includes industrial design and product redesign, sensors and control systems, robotics technical innovation, and digital software solutions.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a monthly summary of our most impactful posts!