Mitigating Diminishing Returns in Extending Product Life: Leveraging Design for X Methodologies

When extending the life of an existing design, one of the significant risks is encountering diminishing returns.

Over time, the cost and effort required to maintain or improve a product may outweigh the benefits, leading to reduced profitability and customer satisfaction. However, by strategically applying Design for X (DFX) methodologies, companies can mitigate the potential cons associated with diminishing returns. These strategies help control costs, sustain product relevance, and ensure long-term reliability, all of which are crucial for avoiding the financial pitfalls of diminishing returns.

Here’s how each DFX methodology can help:

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

(continued from above)

Design for Manufacturability (DFM)

How DFM Mitigates Diminishing Returns: DFM focuses on optimizing the manufacturing process to reduce costs and increase efficiency. By continuously improving manufacturability, companies can maintain profitability even as the product ages, countering the effects of diminishing returns.

Application:

- Cost Reduction: Streamlining manufacturing processes can lower production costs, allowing the company to maintain margins despite the product's maturity.

- Efficiency Gains: Improved manufacturing efficiency can lead to faster production times and reduced waste, which helps sustain profitability.

Design for Assembly (DFA)

How DFA Mitigates Diminishing Returns: DFA aims to simplify the assembly process, reducing time and labor costs. By making the product easier and cheaper to assemble, companies can extend its life without incurring high costs that would otherwise lead to diminishing returns.

Application:

- Simplified Assembly: Reducing the complexity of assembly can lower labor costs and decrease the time needed to bring products to market, helping to preserve profit margins.

- Consistent Quality: Simplified assembly processes also lead to fewer errors, ensuring consistent product quality and customer satisfaction, which is crucial for long-term profitability.

Design for Cost (DFC)

How DFC Mitigates Diminishing Returns: DFC ensures that cost considerations are integrated into every stage of the product’s lifecycle. By controlling costs effectively, companies can avoid the erosion of profits that often accompanies the later stages of a product’s life.

Application:

- Cost Management: DFC can identify and eliminate unnecessary costs, allowing the company to sustain its profitability as the product ages.

- Value Optimization: By focusing on cost without sacrificing quality, companies can continue to offer competitive pricing, maintaining customer demand and market share.

Interested in providing your product development team with DFX skills? Learn More about our Applied DFX process and development workshops.

(continued from above)

Design for Testability (DFT)

How DFT Mitigates Diminishing Returns: DFT ensures that products can be easily tested, which helps maintain quality and reliability over time. This reduces the risk of defects and recalls, which can be costly and damaging to profitability as the product matures.

Application:

- Efficient Testing: Streamlined testing processes can reduce the time and resources required for quality assurance, helping to control costs and prevent diminishing returns.

- Reliability Maintenance: Consistent product testing ensures reliability, reducing the likelihood of costly issues that could impact long-term profitability.

Design for Reliability (DFR)

How DFR Mitigates Diminishing Returns: DFR focuses on ensuring that products remain reliable throughout their lifecycle. By designing for reliability, companies can extend the product’s useful life and reduce the costs associated with repairs and replacements, which can help mitigate diminishing returns.

Application:

- Extended Product Life: By ensuring long-term reliability, companies can avoid frequent redesigns or replacements, sustaining profitability over a longer period.

- Reduced Warranty Costs: Reliable products result in fewer warranty claims and lower after-sales service costs, preserving profit margins.

Design for Serviceability/Maintainability (DFS)

How DFS Mitigates Diminishing Returns: DFS ensures that products are easy to service and maintain, which can reduce the costs associated with after-sales support. By minimizing maintenance costs, companies can mitigate the financial impact of diminishing returns.

Application:

- Reduced Maintenance Costs: Products designed for easy serviceability require less costly maintenance, helping to maintain profitability.

- Enhanced Customer Satisfaction: Easier maintenance can lead to higher customer satisfaction, supporting continued sales and reducing the risk of diminishing returns.

Design for Usability (DFU)

How DFU Mitigates Diminishing Returns: DFU focuses on ensuring that products are user-friendly. By improving usability, companies can keep the product relevant and desirable to customers, even as it ages, thus avoiding the decline in demand that leads to diminishing returns.

Application:

- Sustained Demand: Enhancing usability can keep the product appealing to customers, ensuring ongoing sales and preventing a drop in revenue.

- Market Relevance: Usable products are more likely to remain relevant in the market, helping to sustain profitability over time.

How DFMo Mitigates Diminishing Returns: DFMo allows for the creation of modular products that can be easily upgraded or customized. This flexibility can extend the product’s life and keep it competitive in the market, helping to mitigate diminishing returns.

Application:

- Upgradeability: Modular designs allow for easy updates and upgrades, keeping the product relevant and reducing the need for complete redesigns.

- Customization: Offering customization options can attract a broader customer base, sustaining sales and profitability.

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

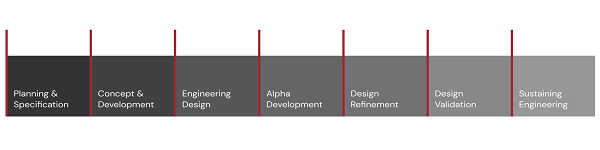

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!

.png)