Boston Engineering: Accelerating Ventilator Development for Global Impact

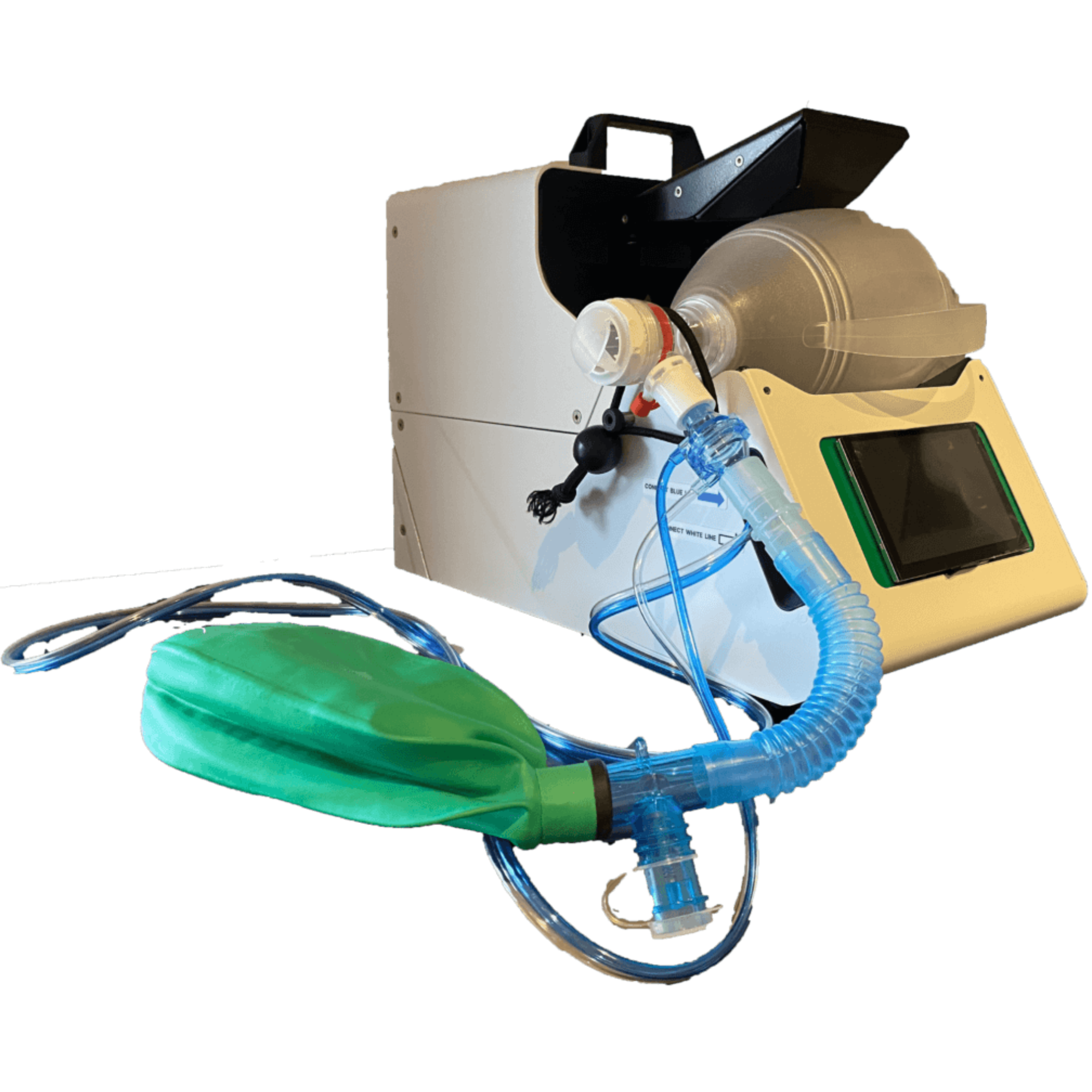

In the face of the global COVID-19 pandemic, the shortage of mechanical ventilators emerged as a critical issue, particularly in underprivileged countries. Boston Engineering, in collaboration with Worcester Polytechnic Institute (WPI), embarked on a groundbreaking project to address this pressing need. This case study explores how Boston Engineering leveraged its medical product development capabilities to design, develop, and deliver open-source mechanical ventilators, showcasing the power of agile innovation and collaboration.

Impetus for Action: As the COVID-19 virus spread, creating a dire need for ventilators, especially in underprivileged nations, Boston Engineering recognized the urgency of the situation. Acting under the FDA's Emergency Use Authorization and with funding from the Massachusetts Manufacturing Emergency Response Team, they joined forces with WPI to initiate a project aimed at rapidly developing mechanical ventilators using readily available components.

Insightful Collaboration: The collaboration between Boston Engineering and WPI was driven by a shared commitment to saving lives. Leveraging the Emergency Use Authorization, the teams worked on an accelerated phase-gate process to design open-source software, electrical circuitry, power, mechanics, and specifications. Remarkably, they cut the typical development time from over 8 months to just 4 months.

Boston Engineering and WPI was driven by a shared commitment to saving lives. Leveraging the Emergency Use Authorization, the teams worked on an accelerated phase-gate process to design open-source software, electrical circuitry, power, mechanics, and specifications. Remarkably, they cut the typical development time from over 8 months to just 4 months.

Impactful Results: The outcomes of this collaborative effort were profound:

-

30 Working Mechanical Ventilators: Boston Engineering and WPI successfully delivered 30 functional mechanical ventilators to over 20 sites in Sub-Saharan Africa.

-

Components for Additional Units: In addition to the ventilators, components for an additional 75 units were provided, facilitating engineering students' and users' study, assembly, and education.

-

Ventilator Training Sessions: Recognizing the importance of proper usage, training sessions and demonstrations on sub-assembly kits were conducted, ensuring that end-users were well-equipped to operate the ventilators effectively.

Press Release Highlights: A press release from November 10, 2021, emphasized the lessons learned during the COVID-19 pandemic, emphasizing the need for agile innovation and collaboration in emergency medical care. WPI Robotics Engineering Professor Greg Fischer highlighted the shift in mindset that enabled the development of low-cost, low-tech solutions, including reconfigured manual ventilators.

Supporting an International Need: The collaboration extended beyond the borders, addressing the shortage of ventilators in Africa. Recognizing the scarcity of ventilators in African countries, Boston Engineering and WPI sent fully assembled ventilators and unassembled ventilator kits to 20 academic institutions. This initiative aims to encourage reverse engineering and co-creation of new ventilators for potential use in hospitals across Africa.

Workforce Development: The project not only saved lives but also contributed to workforce development. High school students, guided by WPI graduate students, gained hands-on manufacturing experience while testing and shipping completed ventilators and kits of parts. This not only enhanced their education but also provided valuable insights into supply chain challenges and global collaborations.

Building on Success: The success of this initiative highlighted the importance of fast turnarounds for emergency product development. R&D facilities like PracticePoint at WPI played a crucial role in testing and prototyping the ventilators, showcasing the need for collaborative spaces that facilitate quick pivots in times of crisis.

Building on Success: The success of this initiative highlighted the importance of fast turnarounds for emergency product development. R&D facilities like PracticePoint at WPI played a crucial role in testing and prototyping the ventilators, showcasing the need for collaborative spaces that facilitate quick pivots in times of crisis.

Boston Engineering's collaborative venture with WPI stands as a testament to the power of innovation, collaboration, and swift action in addressing critical global challenges. By leveraging their medical product development capabilities, these organizations not only saved lives during the pandemic but also contributed to workforce development and set a precedent for future emergency responses.

For almost three decades, Boston Engineering has designed, developed, and optimized devices and technologies the medical community relies on to save lives, enrich quality of life, and reduce costs to the healthcare system. We provide solutions to the challenges in the adoption of surgical robotics.

Our expertise includes industrial design and product redesign, sensors and control systems, robotics technical innovation, and digital software solutions.

Imagine your Impact: Stay up-to-date with the latest insights and trends we're watching. Add your email address below and sign up for a monthly summary of our most impactful posts!