How The Five Tenets of Smart Operations Drive Real Business Impact

Organizations are no longer just looking to automate—they’re aiming to become smarter, faster, and more resilient. Smart Operations offer a framework to do just that, blending automation, AI, connectivity, and real-time data into a unified strategy that delivers measurable business outcomes.

At Boston Engineering, we help companies design and implement Smart Operations that not only improve efficiency on the factory floor, but also drive long-term strategic value across the enterprise.

At the heart of any successful smart operations initiative are five foundational tenets—and understanding these can help your business identify where transformation will deliver the greatest impact.

What Are Smart Operations?

Smart Operations represent the integration of advanced technologies like AI, IoT, automation, and real-time analytics into your daily workflows to create an intelligent, interconnected, and efficient organization. These systems empower companies to:

-

Make real-time, data-informed decisions

-

Predict and prevent downtime

-

Increase operational agility

-

Minimize waste and energy use

-

Ensure systems adapt to disruption and recover rapidly

Unlike conventional digitization efforts, smart operations reimagine how work gets done across functions. They are not just about software adoption—they are about transforming infrastructure, workforce, processes, and culture to continuously optimize performance.

Continue reading below to learn more

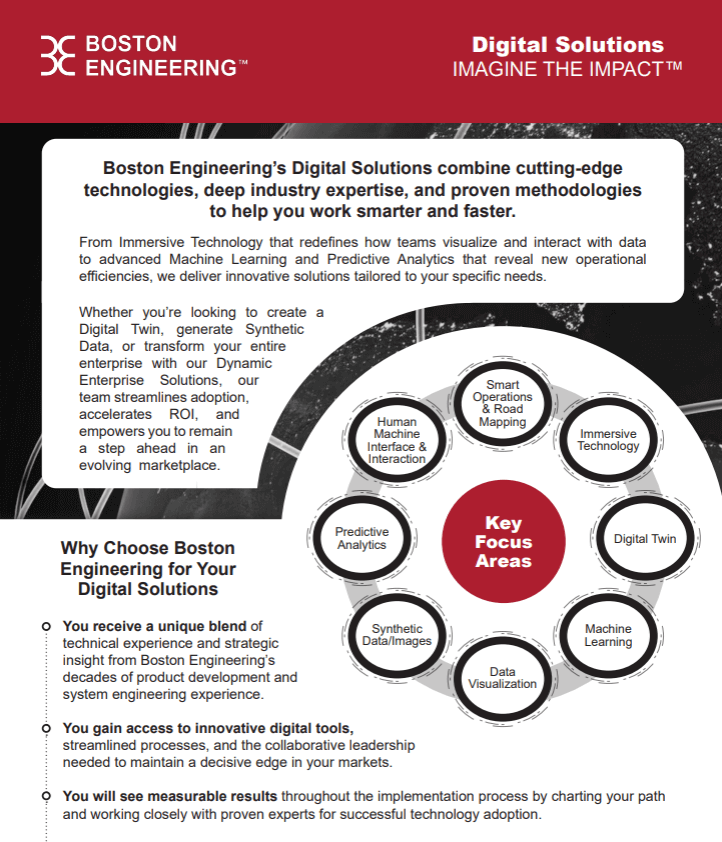

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

The Five Tenets of Smart Operations

To achieve success, your strategy should align with five foundational principles:

-

Connectivity & Data-Driven Decision-Making

Smart operations begin with the ability to capture and analyze data in real time. Using IIoT sensors and connected systems, businesses gather insights into everything from machine health to production bottlenecks. Decisions are made not by gut feel, but by real-time performance metrics, ensuring accuracy, agility, and efficiency. -

Automation & Intelligent Control

Automation tools—augmented by artificial intelligence—replace repetitive and manual tasks with intelligent, self-regulating systems. Whether on the factory floor or in back-office logistics, smart controls continuously adjust processes in real-time, leading to fewer errors and improved productivity. -

Predictive & Proactive Maintenance

Rather than reacting to machine failure, predictive systems monitor equipment health and alert operators before breakdowns occur. This proactive approach minimizes downtime, reduces repair costs, and extends the lifespan of capital assets—ensuring maximum uptime. -

Agility & Scalability

Smart operations are inherently adaptive. Modular systems and scalable software architectures enable companies to pivot quickly—whether scaling up production, launching new services, or responding to supply chain disruptions. The result is a business that’s responsive, flexible, and future-ready. -

Sustainability & Resilience

The final tenet recognizes that long-term performance requires environmental responsibility and operational resilience. Smart operations minimize energy and resource consumption through AI-driven optimization. At the same time, they enhance business resilience—ensuring continuity amid supply chain issues, labor shortages, or other disruptions by using intelligent automation, flexible workflows, and decentralized decision-making.

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Smart Operations Outcomes Explained

Connectivity & Data-Driven Decision-Making

What it is:

Smart operations begin with the ability to capture and analyze data in real time. Using IIoT sensors and connected systems, businesses gather insights into everything from machine health to production bottlenecks. Decisions are made not by gut feel, but by real-time performance metrics, ensuring accuracy, agility, and efficiency.

Business Impact:

- Improved operational transparency enables faster root cause analysis and problem resolution.

- Real-time reporting supports more accurate forecasting, scheduling, and resource planning.

- Data-driven performance insights help identify underperforming assets or workflows, leading to continuous improvement.

When data is democratized across systems and teams, companies can make better decisions faster—turning insights into action and gaining a clear edge over competitors.

Automation & Intelligent Control

What it is:

Automation tools—augmented by artificial intelligence and machine learning—replace repetitive and manual tasks with intelligent, self-regulating systems. Whether on the factory floor or in back-office logistics, smart controls continuously adjust processes in real-time, reducing errors and increasing productivity.

Business Impact:

- Labor-intensive tasks are automated, allowing your workforce to focus on higher-value, strategic activities.

- Reduced cycle times and fewer defects lead to faster, more reliable production output.

- Automated adjustments help maintain process consistency and compliance with quality standards.

By building intelligent control into operations, companies achieve more predictable outcomes, fewer errors, and higher throughput—all while lowering costs.

Predictive & Proactive Maintenance

What it is:

Rather than reacting to machine failure, predictive systems monitor equipment health and alert operators before breakdowns occur. This proactive approach minimizes downtime, reduces repair costs, and extends the lifespan of capital assets—ensuring maximum uptime.

Business Impact:

- Avoid unplanned downtime that disrupts production schedules and customer commitments.

- Reduce maintenance costs by fixing only what needs attention—when it needs attention.

- Increase asset utilization and ROI by extending equipment life and improving reliability.

When your operations are proactive instead of reactive, your business becomes more efficient, more consistent, and less vulnerable to disruption.

Agility & Scalability

What it is:

Smart operations are inherently adaptive. Modular systems and scalable software architectures enable companies to pivot quickly—whether scaling up production, launching new services, or responding to supply chain disruptions. The result is a business that’s responsive, flexible, and future-ready.

Business Impact:

- Shorter time-to-market for new products or services.

- Greater ability to respond to customer demand and changing market conditions.

- Technology investments scale with the business, supporting sustainable growth.

Agility is the new competitive advantage—and with smart operations, your infrastructure and systems can evolve in lockstep with your strategic goals.

Sustainability & Resilience

What it is:

The final tenet recognizes that long-term performance requires both environmental responsibility and operational resilience. Smart operations minimize energy and resource consumption through AI-driven optimization. At the same time, they enhance business continuity by using intelligent automation, flexible workflows, and decentralized decision-making.

Business Impact:

- Lower energy usage and waste generation supports cost savings and ESG goals.

- Intelligent resource management improves efficiency and compliance with regulatory frameworks.

- Built-in redundancy and automation protect your operations from external shocks like labor shortages or supply chain disruptions.

Sustainability isn’t just good for the planet—it’s good for business. Resilient systems are better equipped to withstand challenges, from economic shifts to operational setbacks.

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!