Four Design for X FAQs from Boston Engineering

Market Feedback is critical to successful Design for X (DFX) outcomes. The following are several Frequently asked questions about DFX and our DFX processes we feel would be helpful for anyone considering using the approach.

DFX, or Design for X, refers to a systematic approach to designing products and processes to achieve specific objectives or characteristics. The "X" represents various targets like manufacturability, reliability, usability, etc. DFX helps companies optimize their products across the entire product lifecycle.

DFX represents a holistic approach to product development that optimizes the design against multiple objectives. At Boston Engineering, DFX is a core part of our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

Isn’t DFX just “Common Sense” or “Just Engineering”?

While sound engineering judgment is important, DFX represents far more than just common sense. There are specific methodologies, tools, and techniques for each DFX discipline that require specialized expertise. For example, our extensive Design for Testability knowledge enables in-depth tradeoff analysis on different testing approaches and root cause analysis. We can determine the optimal strategies to verify reliability and performance while minimizing test costs and lead time. Years of experience across diverse industries and products gives us broad perspective on DFX best practices.

Do you use the Boothroyd Dewhurst DFMA® methods and software?

Boothroyd Dewhurst has developed a widely used DFMA methodology and software. While we don't currently use their specific toolset, we employ proven DFMA principles honed over decades of product development experience. Our toolkit includes checklist-based manual techniques as well as advanced parametric 3D modeling capabilities. We’re vendor neutral in our process – the goal is optimizing designs for manufacturing and assembly rather than using specific software. And we achieve this for products ranging from low volumes to over 100M units annually.

Don’t Contract Manufacturers do a better job with DFA and DFM because they do the manufacturing onsite?

While contract manufacturers have expertise in their own processes, we take an agnostic approach to identify the optimum design for the product and volumes at hand. Our full lifecycle perspective encompasses everything from low-volume machined parts to globally distributed high-volume electronics. Years of experience across this spectrum gives us unique insight into design choices that balance performance, quality, and cost. We engage Contract Manufacturers early in design development to incorporate manufacturing feedback. But our independence means we can objectively weigh manufacturing tradeoffs to make the right decisions for the product and business.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

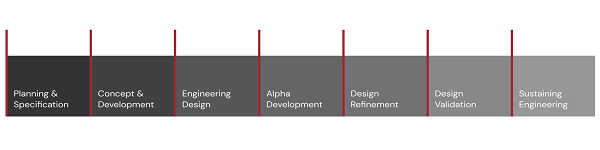

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!