3 Ways Digital Solutions are Positively Impacting Surgical Robotic Technology

Medical device companies are facing a changing regulatory environment that can lead to time-to-market delays, higher costs, and delays in collaboration agility and efficiency across product lifecycles.

From engineering design handover to manufacturing, to traceability and collecting audit-ready data, medical technology professionals are primed for digital transformation across the enterprise to address these challenges and help them achieve their business goals. These digital solutions are providing insights and opportunities for training and maintenance, design updates and improvements, and real-time surveillance.

3 Ways Digital Solutions are Positively Impacting Surgical Robotic Technology

Real-time Monitoring: Real-time visibility into how your processes, people, and products function is key to improving efficiency, safety, service, and compliance. Companies can increase uptime, enable predictive maintenance, and access critical insights that increase efficiency and operational safety through collecting and analyzing data that most modern devices already make available.Not only does this data provide insights for future improvements, but it also can alert companies to necessary maintenance before a machine fully breaks down, limiting downtime and safety issues. Recent analysis has shown the potential for:

- Up to 48% fewer safety incidents

-

Up to 30% less unscheduled downtime

- Up to 50% improvement in OEE

Another related potential for data collection through utilizing current digital technologies is Post-market surveillance (PMS). To gain timely insights into field use, medical device firms are incorporating sensors into their product designs to monitor safety, performance, and usage trends. Collecting data from devices in the field provides critical insights through capabilities to gain live product performance monitoring and to apply analytics to improve business operations. To gain timely insights into field use, medical device firms are incorporating sensors into their product designs to monitor safety, performance, and usage trends..png?width=240&height=160&name=Q2%20campaign%20social%20images%20(1).png) Maintenance & Training: An unexpected breakdown or malfunction can lead to hazardous conditions for both doctors and patients. Reliability risks such as constant maintenance and unplanned downtime not only causes safety and accuracy issues but can cost health care organizations up to $700 per minute in lost revenue! Real-time monitoring provides insights into maintenance issues before they become bigger problems: by predicting when a malfunction may occur, service can be carried out before a major downtime incident.

Maintenance & Training: An unexpected breakdown or malfunction can lead to hazardous conditions for both doctors and patients. Reliability risks such as constant maintenance and unplanned downtime not only causes safety and accuracy issues but can cost health care organizations up to $700 per minute in lost revenue! Real-time monitoring provides insights into maintenance issues before they become bigger problems: by predicting when a malfunction may occur, service can be carried out before a major downtime incident.

Utilizing concepts like the Internet of Things (IoT) and technologies like Augmented Reality (AR) will provide users with virtual maintenance assistance and training, reducing the overall cost of maintenance and equipment downtime. By modernizing training methods, companies can gain immediate access to remote expertise, data visualization, and remote service, allowing new employees to learn from experienced technician while on the job. Training costs can be reduced by up to 50% with AR as the technology, while also reshaping how frontline employees acquire knowledge and digitally interact with their physical surroundings. The Result: faster execution, less manual processes, and better decision making.

Product Development & Design: Boost efficiency, ensure products cost less to produce, and increase reliability by validating that designs are meeting market requirements (and require less maintenance and fewer repairs).

products cost less to produce, and increase reliability by validating that designs are meeting market requirements (and require less maintenance and fewer repairs).

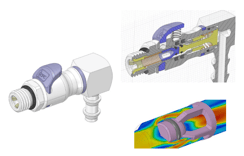

What was traditionally done using manual drafting can now be replaced with custom software designs, allowing designers and engineers to iterate designs faster, reduce costs by forgoing prototyping costs and materials waste, and improve overall product quality.

When products are tested for real-world conditions through simulation against real-time performance data, you can ensure they’re designed to run to spec—eliminating both reworks to solve for design failures and extra service calls for maintenance and repair. Advanced Software Solutions (Including CAD and Simulation options) provide product design and validation before the product is on the market.

For almost three decades, Boston Engineering has designed, developed, and optimized devices and technologies the medical community relies on to save lives, enrich quality of life, and reduce costs to the healthcare system. We provide numerous solutions to the challenges in the adoption of surgical robotics.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a monthly summary of our most impactful posts!