Design for X Methodology Applied to Leverage a Medical Product's Proven Track Record

Design for X (DFX) methodology can be applied to leverage and enhance a proven track record when extending the life of an existing medical product design

By applying DFX methodologies with a focus on leveraging and enhancing a proven track record, medical device companies can extend the life of existing products while reinforcing their reputation for quality and reliability. This approach allows for meaningful product improvements and updates that build upon the established trust and performance history.

Key benefits of this approach include:

- Enhanced market confidence: Building on a proven track record can increase trust among healthcare providers and patients.

- Regulatory advantages: A history of safe and effective use can potentially streamline regulatory processes for product updates.

- Reduced development risks: Leveraging proven components and design principles can minimize the likelihood of unforeseen issues.

- Strong marketing position: A solid track record provides a foundation for compelling marketing messages about product reliability and evolution.

- Customer retention: Consistently meeting or exceeding expectations helps maintain customer loyalty in a competitive market

By focusing on the proven track record in the redesign process, companies can maintain their market position, reinforce customer trust, and create a strong foundation for future innovations. This approach not only extends the product lifecycle but also strengthens the company's brand reputation in the healthcare industry, where reliability and consistent performance are paramount.

Let's dive deeper to understand how each design area can leverage a proven track record to both successfully extend the life of an existing medical product design and gain new customers for the product.

The focus and discipline of DFX is a powerful tool if used as part of a broader strategic approach to developing product/process differentiation, and a sustainable advantage against competition. Involve Design for X in Strategy. Once your team has determined the focus of your strategy, place the focus of design on developing competitive advantage.

At Boston Engineering, DFX is a core part of creating values during our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

The following are illustrative examples of a potential product design decisions a company might make to take strategic advantage of the noted benefits of introducing a new product to market vs. updating an existing product. The cases are presented to evoke thoughts and questions around the potential business case for such decisions, and the reasoning behind each.

(continued from above)

Design for Manufacturability (DFM)

Example: For the pacemaker with extended battery life

A DFM expert could focus on:

- Maintaining or improving manufacturing precision to uphold the product's reputation for reliability

- Optimizing processes to ensure consistent quality across increased production volumes

- Implementing advanced quality control measures that build on existing successful practices

Proven track record benefit: Continued high-quality production, reinforcing the product's established reputation for reliability.

Design for Assembly (DFA)

Example: For the surgical robot with advanced instruments

Working with a DFA expert might involve:

- Designing new components to integrate seamlessly with the proven core system

- Ensuring assembly processes maintain or improve on the existing product's low defect rates

- Creating modular upgrades that don't compromise the integrity of the base unit

Proven track record benefit: Consistent quality and performance across product iterations, maintaining trust in the brand.

Design for Cost (DFC)

Example: For the orthopedic implant with improved materials

A DFC expert could suggest:

- Optimizing material usage to maintain or improve durability while managing costs

- Identifying process improvements that reduce manufacturing costs without compromising quality

- Designing for economies of scale to support wider adoption of the proven technology

Proven track record benefit: Sustained or improved value proposition, reinforcing the product's market position.

Design for Testability (DFT)

Example: For the ventilator with new software features

DFT considerations might include:

- Expanding existing successful testing protocols to cover new features comprehensively

- Designing built-in diagnostics that complement the product's history of reliable performance

- Developing enhanced quality assurance measures that build on the product's track record

AL & ML in Health Care - The Medical Workplace Multiplier

In this new Whitepaper, learn how AI and ML can enhance the medical workforce’s abilities and improve patient outcomes.

In this new Whitepaper, learn how AI and ML can enhance the medical workforce’s abilities and improve patient outcomes.

While some view AI as a potential job replacement threat, the reality is that these advanced capabilities are better positioned as “workforce multipliers” that will amplify the abilities of doctors, nurses, technicians and other medical professionals.

Download your Free Copy Today!

Artificial intelligence and machine learning are emerging technologies that have immense potential to reshape healthcare delivery and medical practice.

Design for Reliability (DFR)

Example: For the infusion pump with updated user interface

A DFR expert might focus on:

- Conducting extensive compatibility testing to ensure new features don't compromise proven reliability

- Implementing predictive maintenance features based on historical performance data

- Designing redundancies and fail-safes that build on the product's history of safe operation

Proven track record benefit: Enhanced reliability features that complement the product's established performance history.

Design for Serviceability/Maintainability (DFS)

Example: For the surgical robot with advanced instruments

DFS considerations could include:

- Designing new components with serviceability features that match or exceed those of proven parts

- Creating upgrade paths that maintain the system's reputation for minimal downtime

- Developing enhanced diagnostic tools that build on the product's history of easy maintenance

Proven track record benefit: Continued or improved ease of maintenance, supporting the product's reputation for reliability and longevity.

Design for Usability (DFU)

Example: For the infusion pump with updated user interface

A DFU expert might suggest:

- Evolving the interface based on extensive user feedback from the existing product

- Designing new features that enhance usability without disrupting proven workflows

- Creating intuitive upgrades that build on users' existing familiarity with the product

Proven track record benefit: Improved user experience that builds on the product's history of user satisfaction and safety.

Example: For the ventilator with new software features

DFMo considerations could include:

- Designing a modular architecture that allows for feature additions without compromising core functionality

- Creating standardized interfaces that support easy integration of proven components with new features

- Developing scalable software platforms that maintain the stability of core functions while allowing for enhancements

New eBook Available Now!

"Leveling Up Existing Products through DFX"

-Download Insights from a DFX Subject Matter Expert-

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

Developing successful new products from scratch is challenging enough, but what about improving on existing designs?

In this eBook, we’ll dive into the real-world experiences of DFX subject matter expert John DePiano, exploring the common areas where existing product owners excel, as well as the key opportunities where targeted DFX support can drive major improvements.

Understanding the Importance of a DFX approach in medical device design & development

Applying Design for X (DFX) methodologies upfront in medical device development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for your medical engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next medical device DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

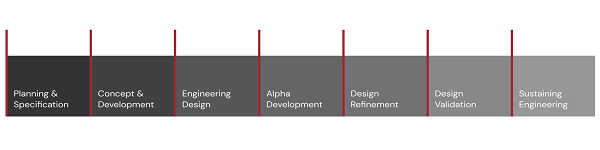

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!

.png)