Building In Reliability Through Design

Design for Reliability (DFX) enables companies to design-in reliability and minimize total cost of ownership.

DFX, or Design for X, refers to a systematic approach to designing products and processes to achieve specific objectives or characteristics. The "X" represents various targets like manufacturability, reliability, usability, etc. DFX helps companies optimize their products across the entire product lifecycle.

DFX represents a holistic approach to product development that optimizes the design against multiple objectives. At Boston Engineering, DFX is a core part of our product development process. We focus on several key DFX areas that align with our expertise:

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Cost (DFC)

- Design for Testability (DFT)

- Design for Reliability (DFR)

- Design for Serviceability/Maintainability (DFS)

- Design for Usability (DFU)

- Design for Modularity (DFMo)

Learn more about Design for X (DFX) at Boston engineering: Boston Engineering Design for X

Product reliability is critical, but reliability issues often arise after launch. Design for Reliability (DFR) aims to bake in reliability upfront.

DFR focuses on meeting reliability goals through robust design.

Key DFR principles include:

- Selecting components with ample quality and ratings

- Performing derating, FMEA, thermal analysis, and other robust engineering methods

- Adding redundancy into the design where needed

- Specifying suitable materials and surface finishes for the operating environment

- Running HALT/HASS testing to uncover failure modes

- Reviewing field performance data to inform reliability improvements

Example Projects:

- Re-qualifying all components on a circuit board for higher temperature rating, eliminating field failures

- Making a robot arm's gripping mechanism redundant to avoid mechanical jams and downtime

Where Problems Arise

Insufficient DFR often results in:

- Frequent field failures and high warranty costs

- Difficulty isolating failure root causes due to lack of design visibility

- Inferior materials and overly tight component tolerances causing latent defects

- Inability to meet customer reliability expectations

Involving DFR experts early in design to prevent these issues.

DFs experts like Boston Engineering provide:

- Physics of failure analysis skills to identify failure mechanisms

- Knowledge of reliability best practices for your type of product

- Awareness of the latest technologies for predictive health monitoring

- Tools to model and quantify reliability metrics

- Guidance to implement DFR principles across the organization

Understanding the Importance of a DFX approach

Applying Design for X (DFX) methodologies upfront in product development optimizes the entire lifecycle by improving manufacturability, testability, reliability, usability, and other critical characteristics. This avoids costly redesigns later on, facilitates high-quality products that satisfy customers, reduces manufacturing and service costs, and supports flexibility through modularity and platforms. The holistic perspective of DFX drives efficient, cost-effective delivery of successful products that provide competitive advantage. Investing in DFX early pays dividends across the entire product lifespan.

Do you offer training on DFX for engineering teams?

Education is critical to effectively implement DFX principles. We provide training tailored to your engineers’ roles and product lines. This includes overall DFX methodology, deep dives into specific disciplines like design for reliability or manufacturability, and practical application workshops. Our hands-on approach combines real-world examples and case studies with tutorials on leading DFX software tools. The goal is building organizational DFX expertise and establishing repeatable processes that endure beyond individual projects. Investing in DFX knowledge pays dividends across your entire product portfolio.

Ready to Begin your next DFX Project?

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

Whether you’ve created a new technology, or have an innovative way to use an existing solution, Boston Engineering will turn your ideas into reality. Our experts and Industry Partners will enhance your current team or manage the entire Product Development Process from Market Analysis to Production. Don't leave complex projects or high visibility product launches to chance. Know you're going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by Novel Engineering. Contact Boston Engineering Today to get started.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

-1.png?width=2000&height=279&name=MED%20Coffee%20Talk%20Mastering%20Use%20Cases%20%26%20Cybersecurity%20(2)-1.png)

Impossible Challenge? Try Us.

Selecting a partner to help you complete your design project is a valuable option to reduce project duration and save money.

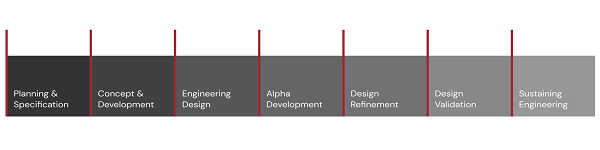

The Boston Engineering product development system encompasses DFX to ensure a smooth product launch and success in the marketplace. Boston Engineering has DFX knowledge and experience to address aspects and values of a product such as manufacturability, test, reliability, safety, serviceability, cost, and compliance with industry standards and government regulations.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!

%2c%20portrating%20innovation%2066653.jpg)