Agility & Scalability: The Competitive Edge in Smart Operations

Companies face unprecedented challenges: market disruptions, supply chain uncertainties, changing customer expectations, and rapid technological advancement. To thrive amidst this complexity, organizations must develop two critical capabilities: agility and scalability.

Smart Operations represents the evolution of modern industry, driven by connected systems, intelligent technologies, and real-time insights. At the heart of this evolution lies Agility and Scalability, foundational capabilities that transform operations from a reactive burden into a strategic advantage.

Why Agility & Scalability Matter Now More Than Ever

Agility is a company's ability to respond quickly to change, pivot when necessary, and seize emerging opportunities. Scalability allows organizations to efficiently expand or contract operations in response to market demands without sacrificing performance or profitability.

Together, these capabilities create a formidable competitive advantage:

- Resilience against disruption: Agile, scalable operations can withstand supply chain shocks, economic downturns, and unexpected challenges

- Rapid response to market changes: Companies can quickly adjust production volumes, introduce new products, or enter new markets

- Optimized resource utilization: Organizations can scale resources precisely to match demand, minimizing waste and maximizing ROI

- Enhanced customer satisfaction: Businesses can adapt to evolving customer needs and preferences in real-time

- Sustainable growth: Companies can expand without proportional increases in operational costs

Smart operations technologies provide the foundation for true agility and scalability. Let's explore how each technology contributes to these crucial outcomes.

Continue reading below to learn more

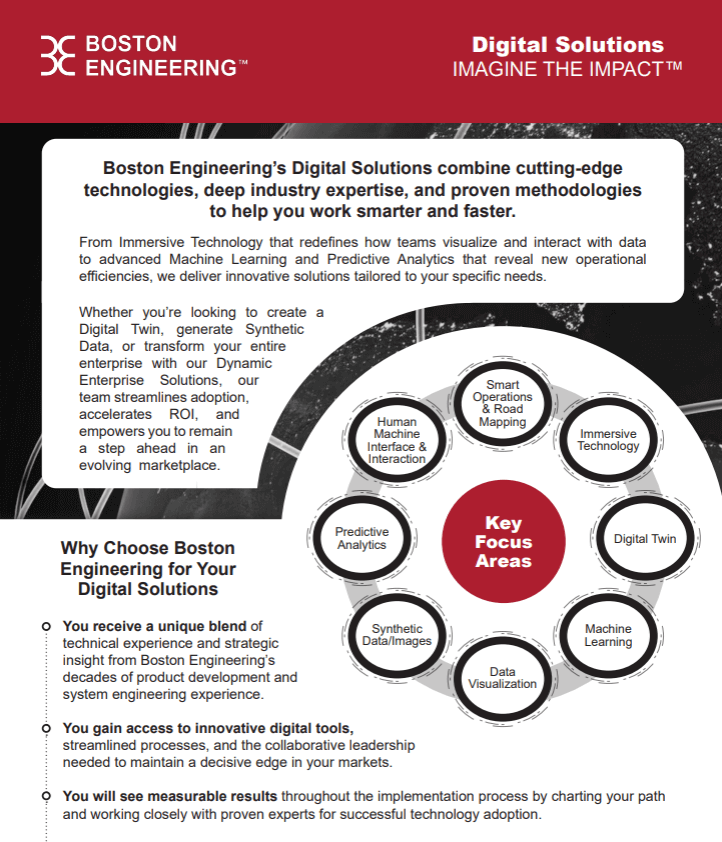

The Boston Engineering Digital Solutions Portfolio

Boston Engineering’s comprehensive Digital Solutions Portfolio brings together cutting-edge technologies and engineering expertise to solve your most complex business challenges.

Download the Boston Engineering Digital Solutions Guide

By leveraging our Digital Solutions Portfolio, you gain a strategic partner committed to delivering measurable improvements in operational efficiency, decision-making capabilities, and competitive advantage. Our solutions span the entire digital transformation spectrum.

Our Discrete Digital Solutions include:

| Immersive Technology | Smart Operations | Digital Twin |

| Synthetic Data & Images | Machine Learning | Data Visualization |

| Predictive Analytics | Human Machine Interface & Interaction | Dynamic Enterprise Solutions |

(continued from above)

Industrial Internet of Things (IIoT)

Technology Overview

The Industrial Internet of Things connects machines, sensors, and systems across operations, creating a network that continuously generates and shares data. This connectivity layer forms the foundation of smart operations, enabling real-time monitoring, control, and optimization.

How It Enables Agility & Scalability

IIoT creates unprecedented operational visibility and flexibility by:

- Providing real-time status of all connected assets and processes

- Enabling remote monitoring and management from anywhere

- Supporting rapid reconfiguration of production systems

- Facilitating data-based decision making for nimble responses

Illustrative Example

A precision manufacturing company implements IIoT sensors across its production facilities, connecting previously isolated equipment to a central monitoring system. When demand patterns shift dramatically during a market disruption, managers can instantly see capacity utilization across all plants, identify underutilized equipment, and redistribute workloads accordingly. The company rapidly shifts production capacity to high-demand product lines, increasing output without additional capital investment. Additionally, when opening a new facility, they replicate the IIoT infrastructure, bringing the new operation online in half the time of previous expansions.

Contact us to talk about similar opportunities in your operations

Robotics & Automation

Technology Overview

Modern robotics and automation systems handle repetitive tasks with precision while offering unprecedented flexibility. Unlike legacy automation, today's systems can be reprogrammed quickly, work safely alongside humans, and adapt to changing production requirements.

How It Enables Agility & Scalability

Advanced robotics supports operational flexibility and growth by:

- Providing modular, reconfigurable production capabilities

- Maintaining consistent quality at any production volume

- Enabling rapid changeovers between product types

- Supporting gradual automation that scales with business needs

Illustrative Example

A mid-sized electronics manufacturer implements collaborative robots (cobots) in its assembly operations. Unlike traditional industrial robots, these cobots require minimal safety barriers and could be reprogrammed for different tasks in under an hour. When a new product opportunity emerges, the company quickly reconfigures its cobots to handle the new assembly requirements without extensive retooling or downtime. Production begins within days rather than weeks. Later, as demand grows, the company simply adds additional cobots to the production line, scaling output without redesigning the entire process. This modular approach allows them to increase production capacity while maintaining quality and reducing per-unit labor costs.

Contact us to talk about similar opportunities in your operations

The 2025 Boston Engineering Technology Overview is Here!

Embrace the future trends that are shaping a new era of engineering excellence. Download for groundbreaking insights!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Access these exclusive technology insights and empower yourself and your organization to stay ahead of the curve. Download your copy of the Boston Engineering 2025 Technology Overview today!

Key Topics:

- Re-shoring as a Competitive Advantage

- Modular Sustainment Robotics

- Embedded Systems

- DFX (Design for X)

- Control Systems

- Digital Solutions

- Mechanical Engineering

- Software Engineering

Download the Boston Engineering 2025 Technology Overview

Artificial Intelligence & Machine Learning (AI/ML)

Technology Overview

AI/ML systems analyze vast amounts of operational data to identify patterns, predict outcomes, and generate actionable insights. These technologies can optimize processes, anticipate issues before they occur, and continuously improve performance through learning algorithms.

How It Enables Agility & Scalability

AI/ML enhances operational responsiveness and adaptability by:

- Predicting demand fluctuations and production requirements

- Identifying process inefficiencies and suggesting improvements

- Enabling dynamic resource allocation based on changing conditions

- Automating complex decision-making for faster responses

Illustrative Example

A consumer packaged goods manufacturer deploys AI/ML technology to analyze market data, production metrics, and supply chain information. The system develops accurate demand forecasts that continuously improved over time, allowing the company to dynamically adjust production schedules. When a competitor's product shortage creates unexpected demand, the AI system detects the pattern within days, recommends production increases, and even suggests optimal distribution strategies to capitalize on the opportunity. The company increases market share by responding faster than competitors. As the business expands to new regions, the ML algorithms quickly adapts to local market patterns, reducing the typical learning curve for entering new territories by months.

Contact us to talk about similar opportunities in your operations

Digital Twin Technology

Technology Overview

Digital twin technology creates virtual replicas of physical assets, processes, or entire operations. These digital models simulate real-world conditions and behaviors, allowing companies to test scenarios and optimizations before implementing them in the physical world.

How It Enables Agility & Scalability

Digital twins enhance operational adaptability and expansion capability by:

- Providing risk-free testing environments for process changes

- Enabling rapid assessment of capacity expansion scenarios

- Supporting virtual commissioning of new equipment

- Facilitating continuous optimization of existing operations

Illustrative Example

An automotive parts supplier creates a digital twin of its entire production facility, modeling all equipment, workflows, and interdependencies. Before launching a major new product line, engineers use the digital twin to simulate different production configurations, identifying potential bottlenecks and optimizing workflows virtually. This approach eliminates weeks of physical trial-and-error and prevents costly mistakes. When the company later needs to double production capacity, the digital twin allows them to simulate multiple expansion scenarios, identifying the optimal solution that required less capital investment than initially planned. The virtual testing environment enables them to scale operations quickly and confidently, bringing new capacity online faster than previous expansions.

Contact us to talk about similar opportunities in your operations

Download the Latest Immersive Technology Whitepaper from Boston Engineering

Augmented Reality (AR) is revolutionizing the way we interact with digital content, merging the physical and digital worlds in innovative ways. In this white paper, we provide a comprehensive overview of AR, exploring its definition, potential uses, challenges in adoption, and strategies for companies to embrace this transformative technology.

Download to begin Embracing the Future

Advanced Control Systems & Embedded Systems

Technology Overview

Advanced control systems coordinate complex operations through sophisticated algorithms and distributed intelligence. Embedded systems—computing devices integrated directly into equipment—enable local processing and control, making equipment smarter and more adaptable.

How It Enables Agility & Scalability

These technologies enhance operational flexibility and expansion capability by:

- Providing granular control over individual processes

- Enabling rapid reconfiguration through software updates

- Supporting modular system architecture that simplifies expansion

- Facilitating coordinated responses across multiple production areas

Illustrative Example

A specialty chemical manufacturer implements advanced control systems with embedded intelligence throughout its batch processing operations. Each production vessel contains embedded systems that monitors conditions and adjusts parameters in real-time, while a central control system coordinates workflows across the entire facility. When customer specifications change unexpectedly, engineers can reconfigure production parameters through software updates rather than equipment modifications. This flexibility allows the company to adapt to custom orders within hours instead of days. When demand increases, the modular nature of the control architecture makes it straightforward to add additional production units without disrupting existing operations. The company expands capacity in a phased approach, maintaining continuous operations throughout the scaling process.

Contact us to talk about similar opportunities in your operations

Cybersecurity & Cloud Computing

Technology Overview

Modern cybersecurity frameworks protect connected operations from threats while enabling safe collaboration. Cloud computing provides scalable computational resources, data storage, and software services without the limitations of on-premises infrastructure.

How It Enables Agility & Scalability

This technological pairing supports operational adaptability and growth by:

- Providing secure access to operational systems from anywhere

- Enabling rapid deployment of new applications without hardware limitations

- Supporting elastic computing resources that scale with demand

- Facilitating secure collaboration across facilities and partners

Illustrative Example

A global food processing company moves its production management systems to a secure cloud infrastructure with robust cybersecurity protocols. This approach allows plant managers and engineers to securely access operational data and controls from any location, significantly improving response times during disruptions. When an unexpected opportunity arises to acquire a competitor, the cloud infrastructure enables rapid integration of the new facilities into existing systems—a process that would have taken months with traditional on-premises systems is completed in weeks. The elastic nature of cloud resources allows the IT infrastructure to scale instantly with the increase in operations, while the comprehensive cybersecurity framework ensures that the expanded digital footprint remains protected. Additionally, the company avoids millions in capital expenditures that would have been required to expand traditional data centers.

Contact us to talk about similar opportunities in your operations

Building Your Agile, Scalable Foundation

Implementing these technologies requires a strategic approach focused on tangible business outcomes rather than technology for its own sake. Organizations should:

- Assess current agility and scalability limitations: Identify where operational rigidity creates vulnerability or hampers growth

- Start with high-impact opportunities: Target specific use cases where agility or scalability directly impacts business performance

- Build with integration in mind: Ensure technologies work together through standardized protocols and platforms

- Develop both technology and talent: Train people to leverage these new capabilities effectively

- Implement iteratively: Deploy technologies in phases, learning and adjusting with each implementation

Conclusion

Operational agility and scalability have transitioned from competitive advantages to essential survival traits. Companies that leverage smart operations technologies to create flexible, adaptable, and scalable operations will not only withstand disruptions but also capitalize on opportunities faster than competitors.

The technologies we've explored—IIoT, AI/ML, Robotics, Digital Twins, Advanced Control Systems, and Cybersecurity/Cloud Computing—each contribute uniquely to building operations that can pivot quickly and grow efficiently. Together, they create an operational foundation that can adapt to almost any market condition or growth opportunity.

As you consider your own smart operations journey, focus on how these technologies can remove the constraints that currently limit your organization's ability to adapt and scale. The resulting operational agility and scalability will provide returns far beyond process efficiency—they'll create the freedom to pursue new opportunities with confidence.

Partner with Boston Engineering to develop your roadmap for connectivity and data-driven decision-making. Our multidisciplinary expertise ensures seamless integration across technologies and systems, delivering transformative results for your operations.

Build Your Smart Operations Strategy with Boston Engineering

At Boston Engineering, we help companies align their smart operations strategies to these five tenets—turning technological potential into measurable business outcomes. Our multidisciplinary expertise in electrical, software, mechanical, and systems engineering, paired with our Centers of Excellence in robotics, digital solutions, control systems, embedded system design, and Design for X, positions us to deliver fully integrated solutions tailored to your goals.

Whether you're just starting your digital journey or looking to scale an existing initiative, we can help you:

- Design intelligent, connected systems.

- Automate and optimize your production workflows.

- Predict maintenance needs and reduce downtime.

- Build resilient, scalable operations for the future.

Smart operations are only successful when companies can overcome the obstacles that stand in their way. The right partner makes all the difference.

Is Your Company Ready for Smart Operations?

Implementing smart operations requires careful planning, the right expertise, and a clear roadmap. The companies that succeed are those that partner with experts who understand how to integrate these advanced technologies seamlessly into their existing workflows.

At Boston Engineering, we specialize in engineering, automation, and smart technology integration, helping businesses:

- Identify the right smart operations strategy based on their unique needs and goals.

- Seamlessly integrate AI, IIoT, robotics, and automation into existing operations.

- Ensure a smooth transition by minimizing downtime and maximizing ROI.

- Develop scalable, future-proof solutions that drive long-term success.

Smart operations aren’t just a passing trend—they are the future of industrial efficiency and growth. Companies that take the first steps today will lead their industries tomorrow.

Contact us today to explore how smart operations can transform your business and position you for long-term success.

No matter the challenge, our team possesses the expertise in the engineering disciplines and technologies you need to bring your vision to life. Impossible Challenge? Try Us.

Imagine your Impact: Stay up-to date- with the latest insights and trends we're watching. Add your email address below and sign up for a Monthly Summary of our most impactful posts!